Search parts

-

Year

Make

Model

Sub Model - Drive Type

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1999

- 1998

- 1997

- 1996

- 1995

- 1994

- 1993

- 1992

- 1991

- 1990

- 1989

- 1988

- 1987

- 1986

- 1985

- 1984

- 1983

- 1982

- 1981

- 1980

- 1979

- 1978

- 1977

- 1976

- 1975

- 1974

- 1973

- 1972

- 1971

- 1970

- 1969

- 1968

- 1967

- 1966

- 1965

- 1964

- 1963

- 1962

- 1961

- 1960

- 1959

- 1958

- 1957

- 1956

- 1955

- 1954

- 1953

- 1952

- 1951

- 1950

- 1949

- 1948

- 1947

- 1946

- 1945

- 1944

- 1943

- 1942

- 1941

- 1940

- 1939

- 1938

- 1937

- 1936

- 1935

-

Results For

-

-

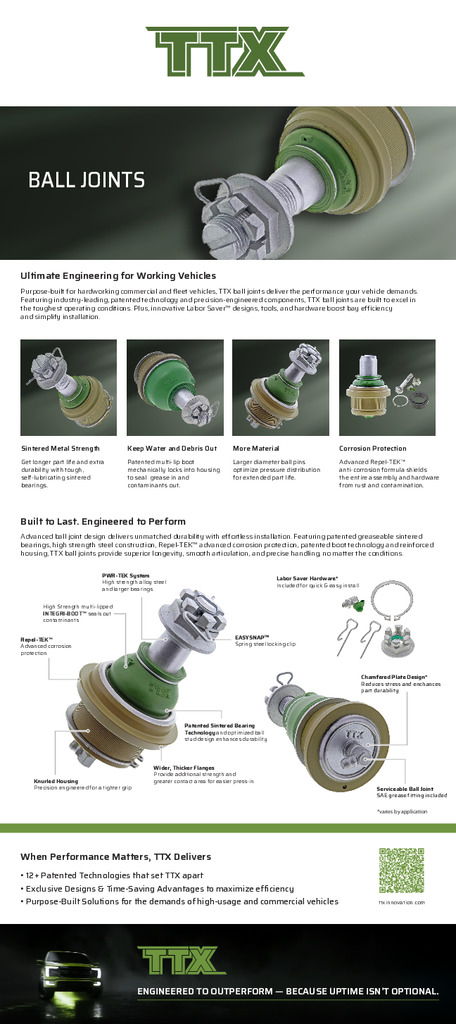

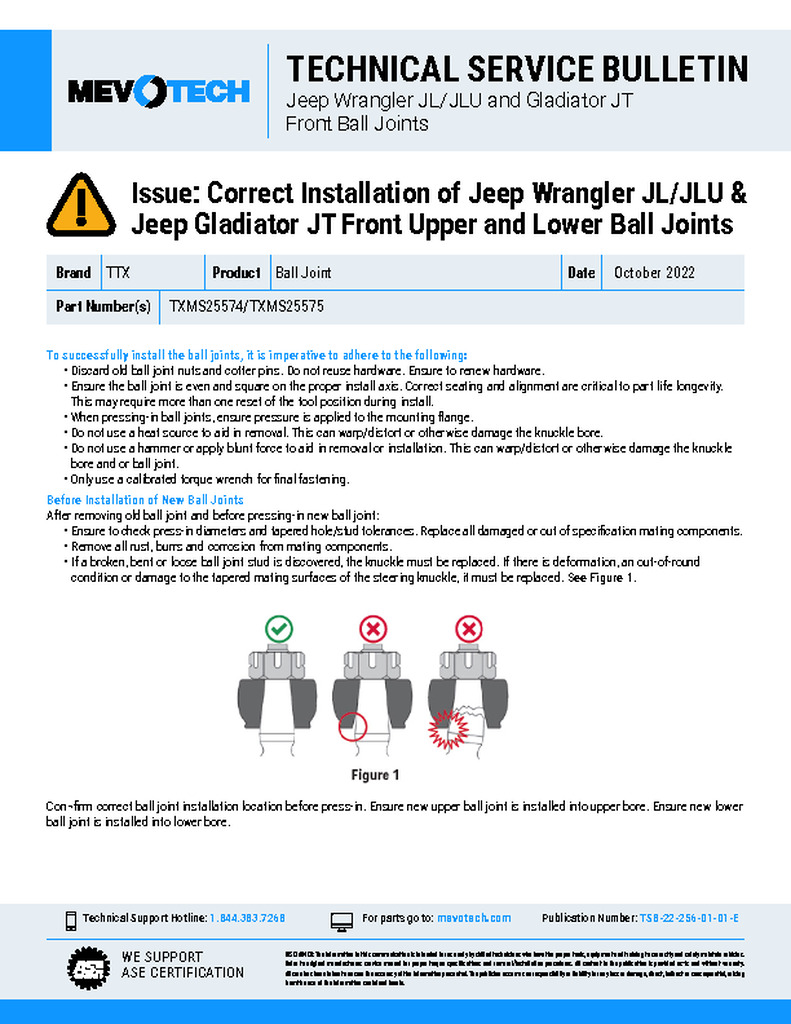

BALL JOINTS

DESIGNED TO OPTIMIZE YOUR RIDE

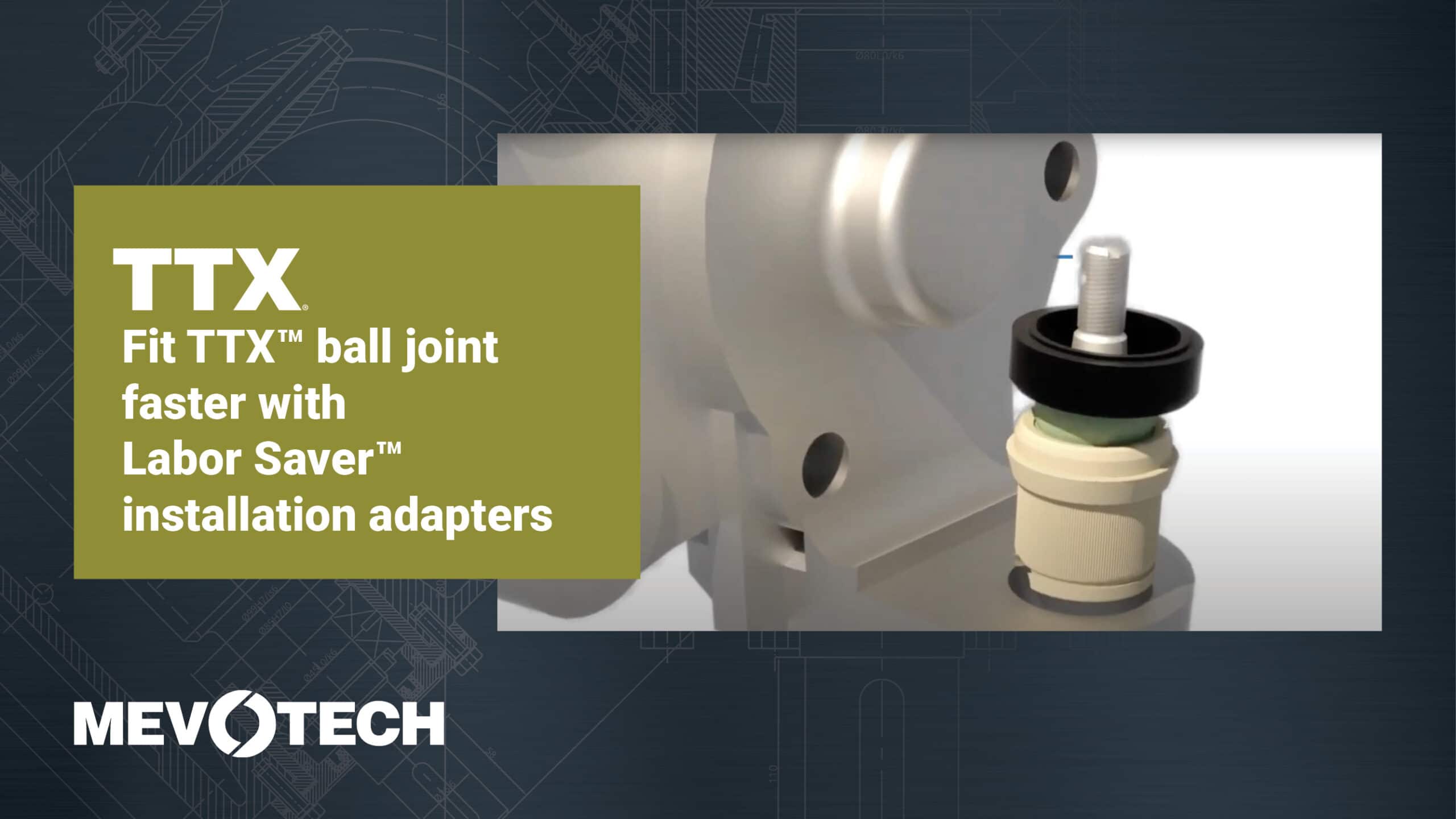

ENGINEERED FOR TECHNICIANS

blackridiminsionato – Village Fitness Club buy testosterone uk nude fitness male vintage videos

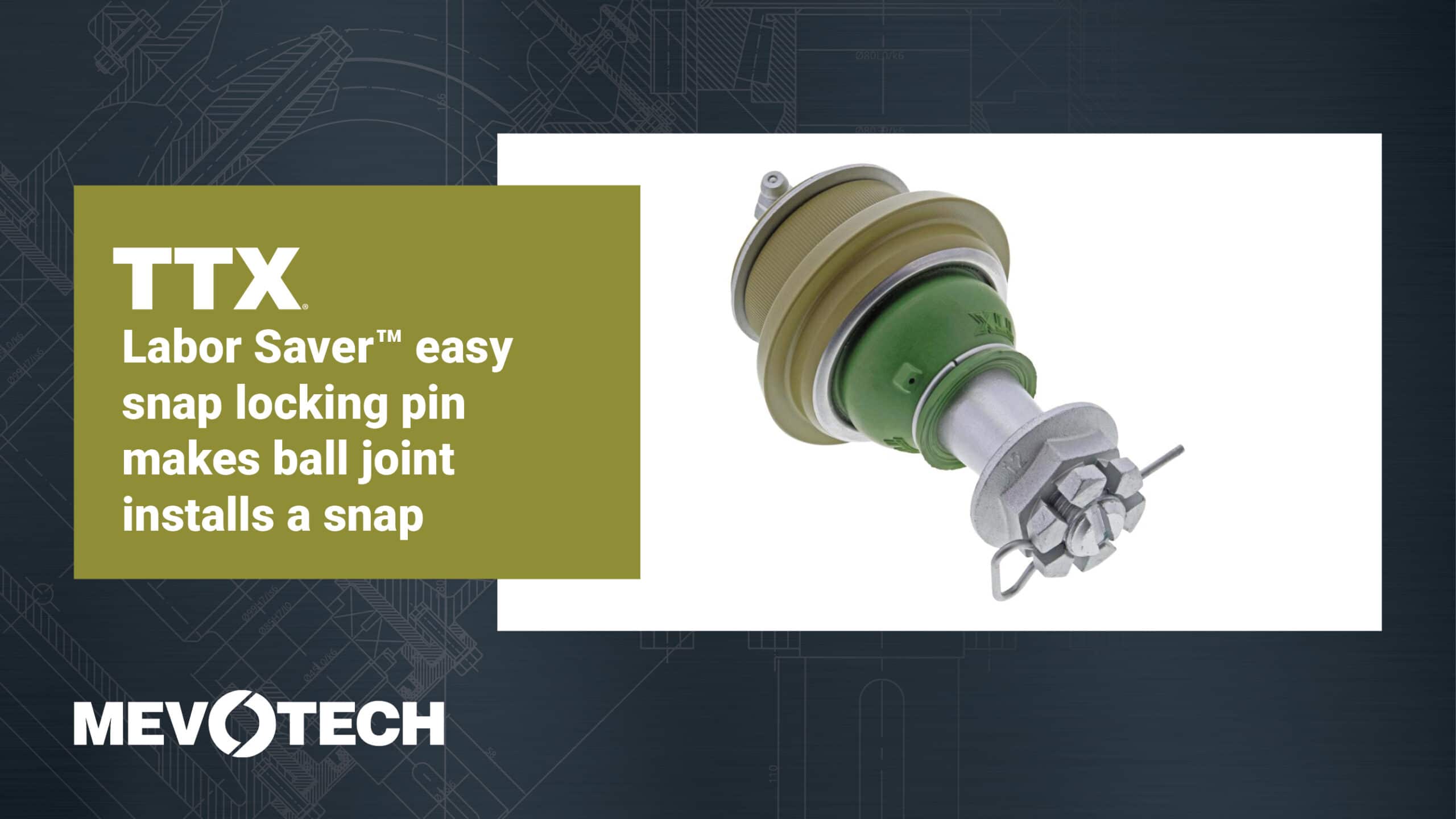

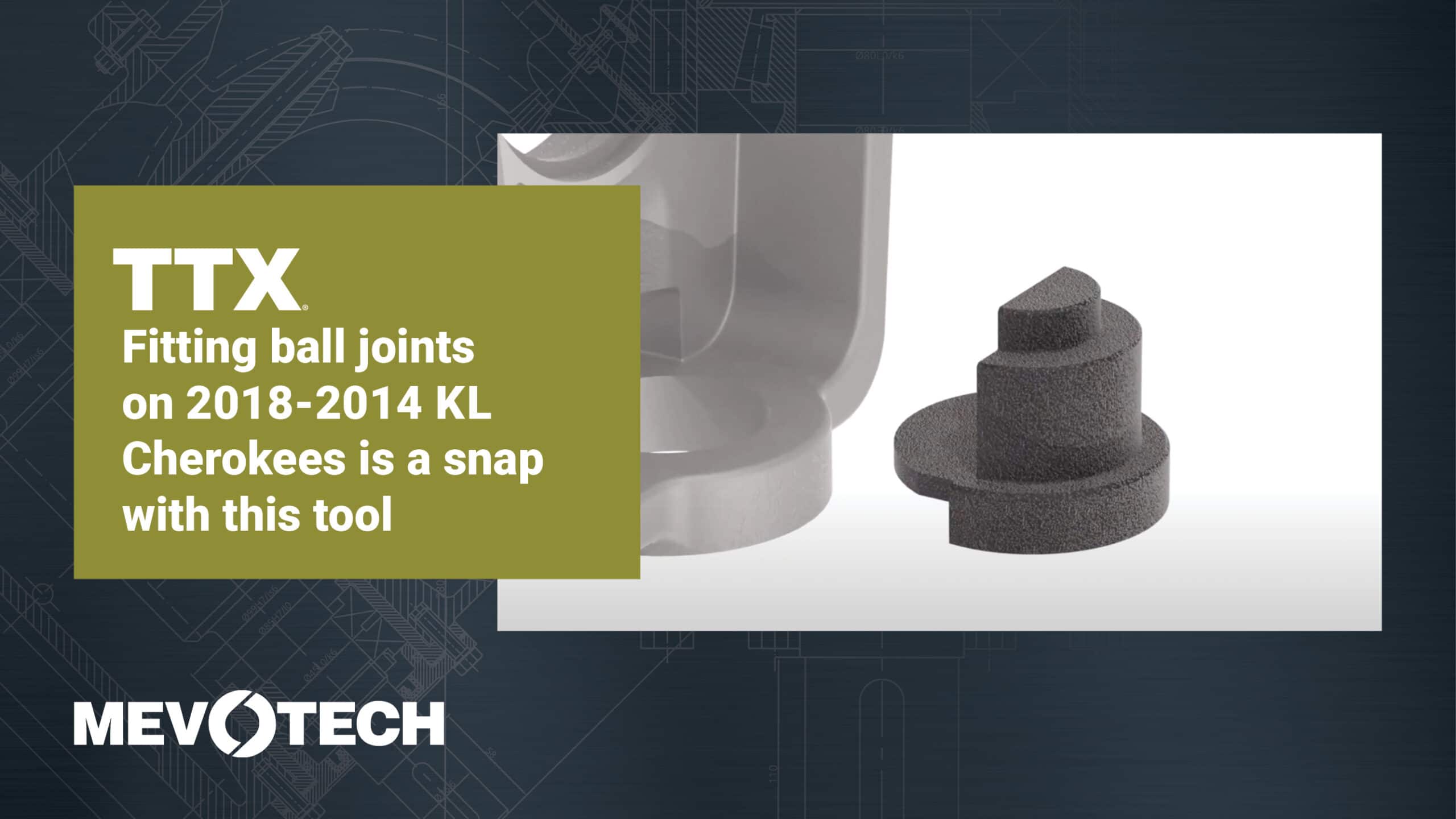

Innovative design. Enhanced durability.

Lasts longer and installs easier with advanced engineering.

Driven by Innovation

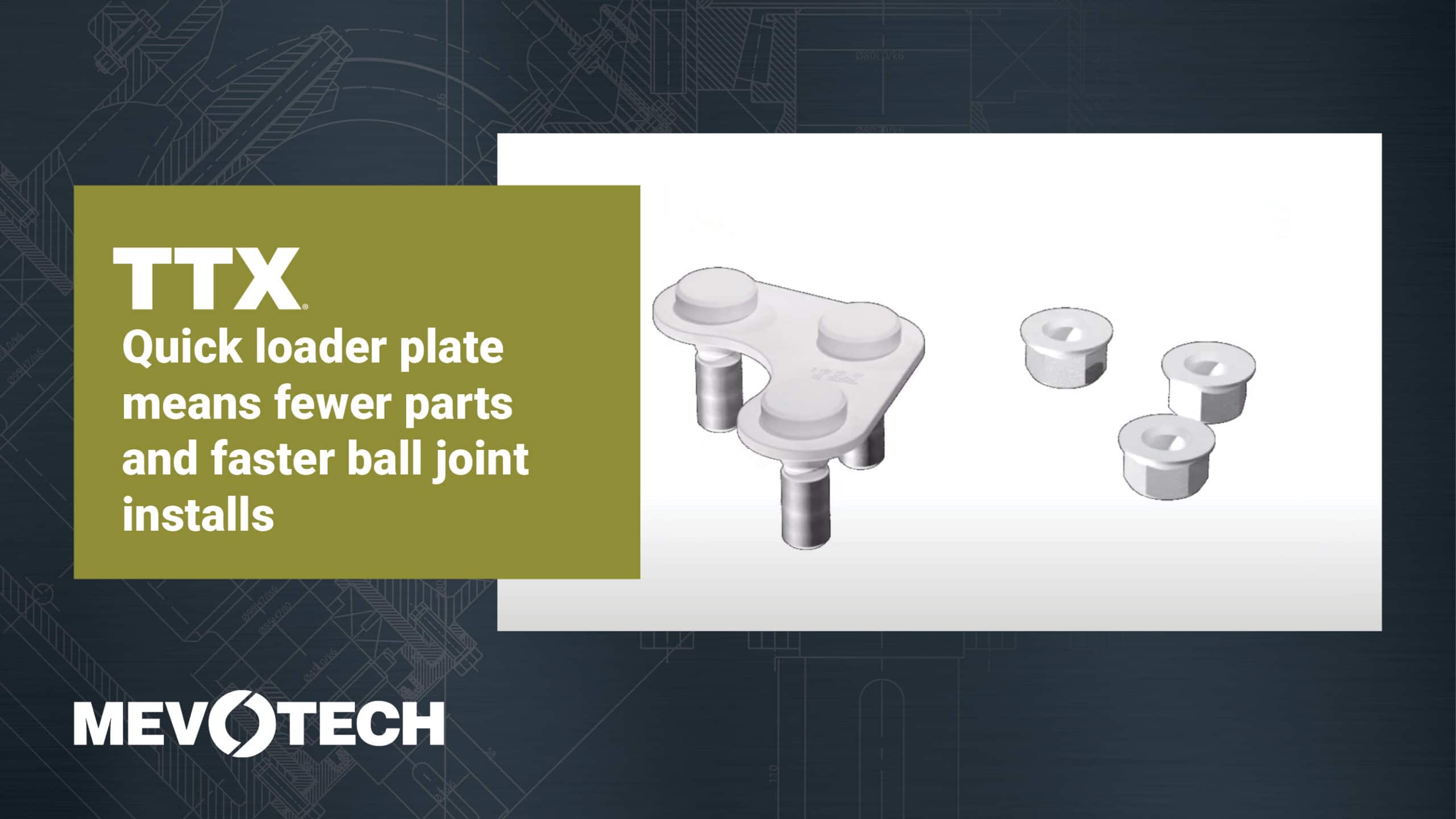

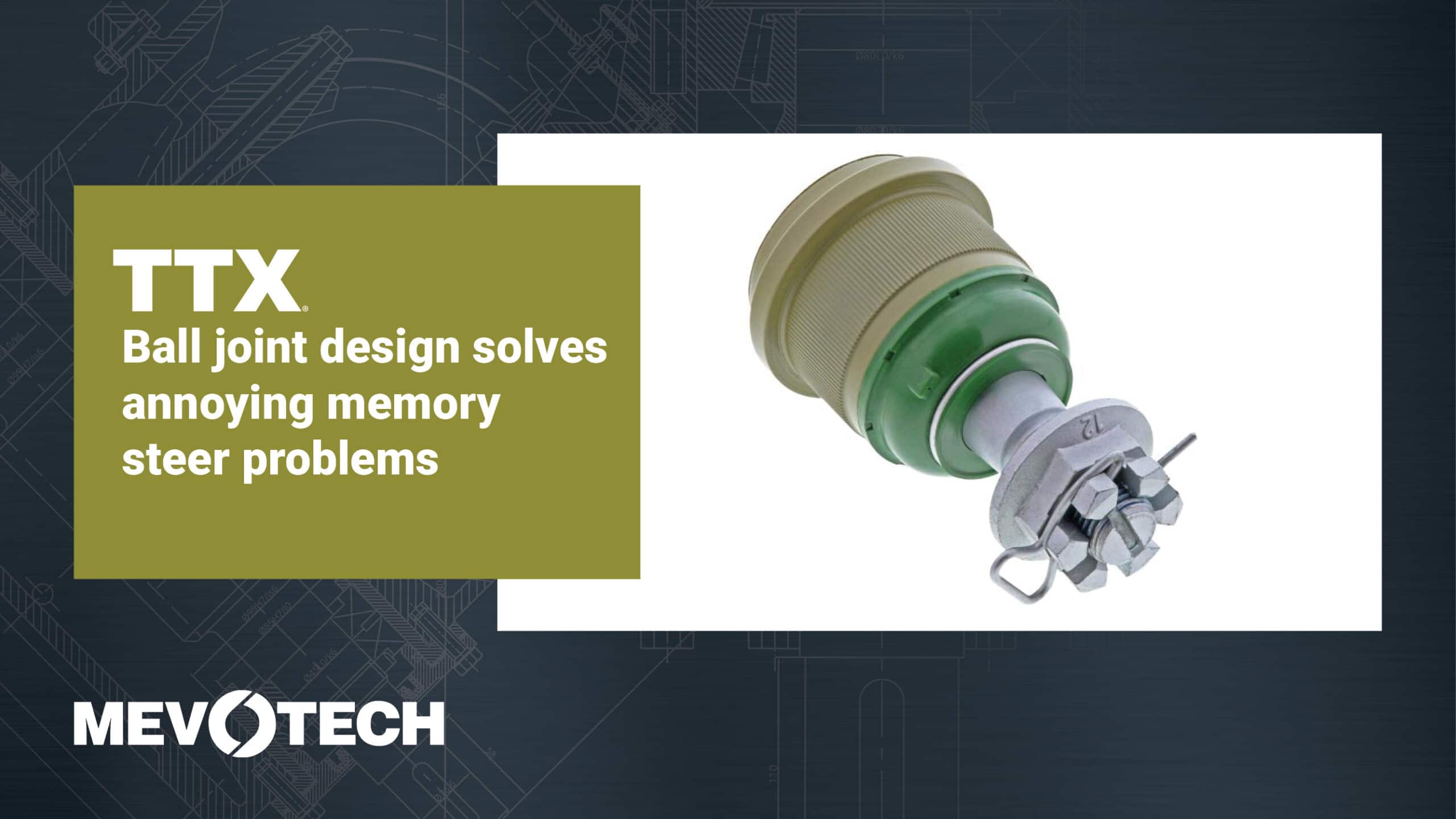

There are no limits. With 12 patented chassis technologies and over a thousand first-to-market exclusives, our innovations meet tough aftermarket challenges head on.

Rigorous Testing

Extensive in-house and third-party durability testing ensures ultimate performance and strength.

Engineered with purpose to go the distance.

Supreme

Superior durability, tested endurance and unsurpassed quality. Ready to go right out of the box.

Original Grade

OE-Grade performance backed by design excellence. Restores performance, handling and ride.

Why Are Ball Joints Important?

Much like human hip joints, ball joints act as pivot points. They are an integral component that connects the various links between your suspension and chassis. As a wheel on your vehicle moves up and down the suspension pivots through ball joints. They allow the suspension to move independently without interfering with the action of the wheel. This independent motion isolates the wheel movement from the chassis, creating a smooth and quiet ride.