Search parts

-

Year

Make

Model

Sub Model - Drive Type

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1999

- 1998

- 1997

- 1996

- 1995

- 1994

- 1993

- 1992

- 1991

- 1990

- 1989

- 1988

- 1987

- 1986

- 1985

- 1984

- 1983

- 1982

- 1981

- 1980

- 1979

- 1978

- 1977

- 1976

- 1975

- 1974

- 1973

- 1972

- 1971

- 1970

- 1969

- 1968

- 1967

- 1966

- 1965

- 1964

- 1963

- 1962

- 1961

- 1960

- 1959

- 1958

- 1957

- 1956

- 1955

- 1954

- 1953

- 1952

- 1951

- 1950

- 1949

- 1948

- 1947

- 1946

- 1945

- 1944

- 1943

- 1942

- 1941

- 1940

- 1939

- 1938

- 1937

- 1936

- 1935

-

Results For

-

-

CONTROL ARMS

#1 CONTROL ARM SUPPLIER IN NORTH AMERICA

ENGINEERED FOR TECHNICIANS

Cutting-edge technology. Industry-leading part coverage.

Installs faster with components preassembled for a complete solution.

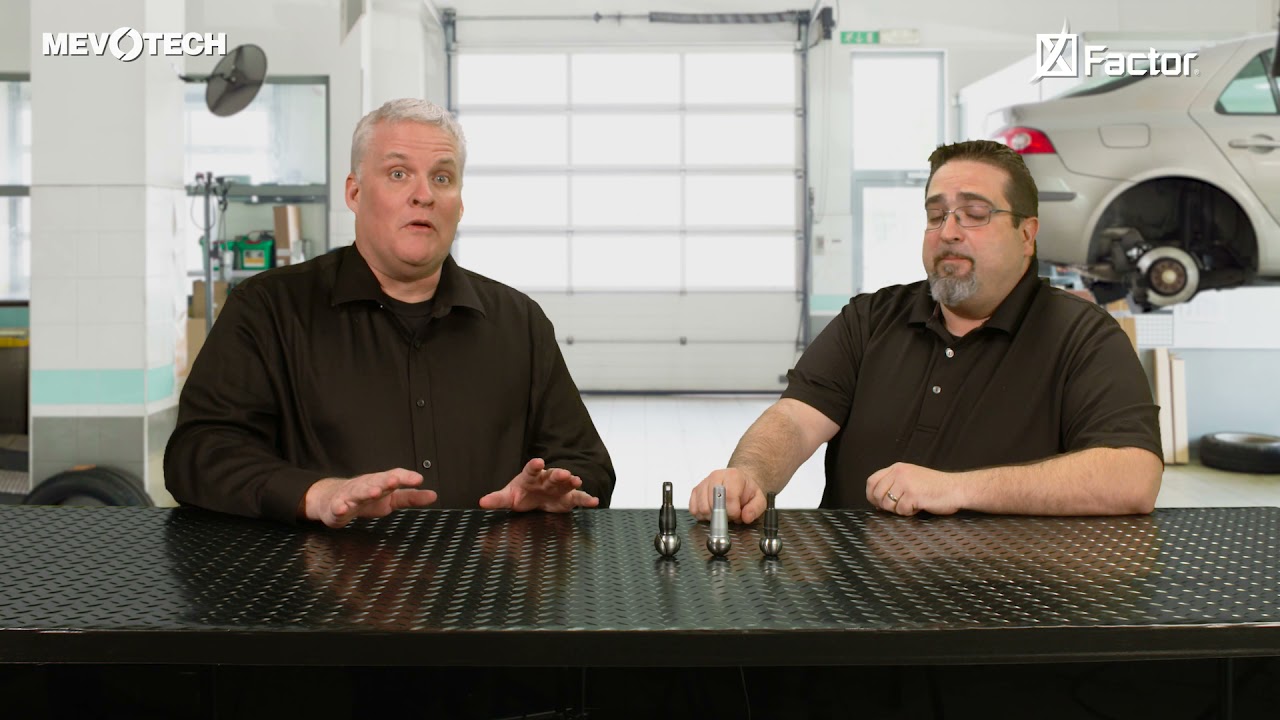

Driven by Innovation

There are no limits. With 12 patented chassis technologies and over a thousand first-to-market exclusives, our innovations meet tough aftermarket challenges head on.

Rigorous Testing

Extensive in-house and third-party durability testing ensures ultimate performance and strength.

Innovation you can trust to keep you moving.

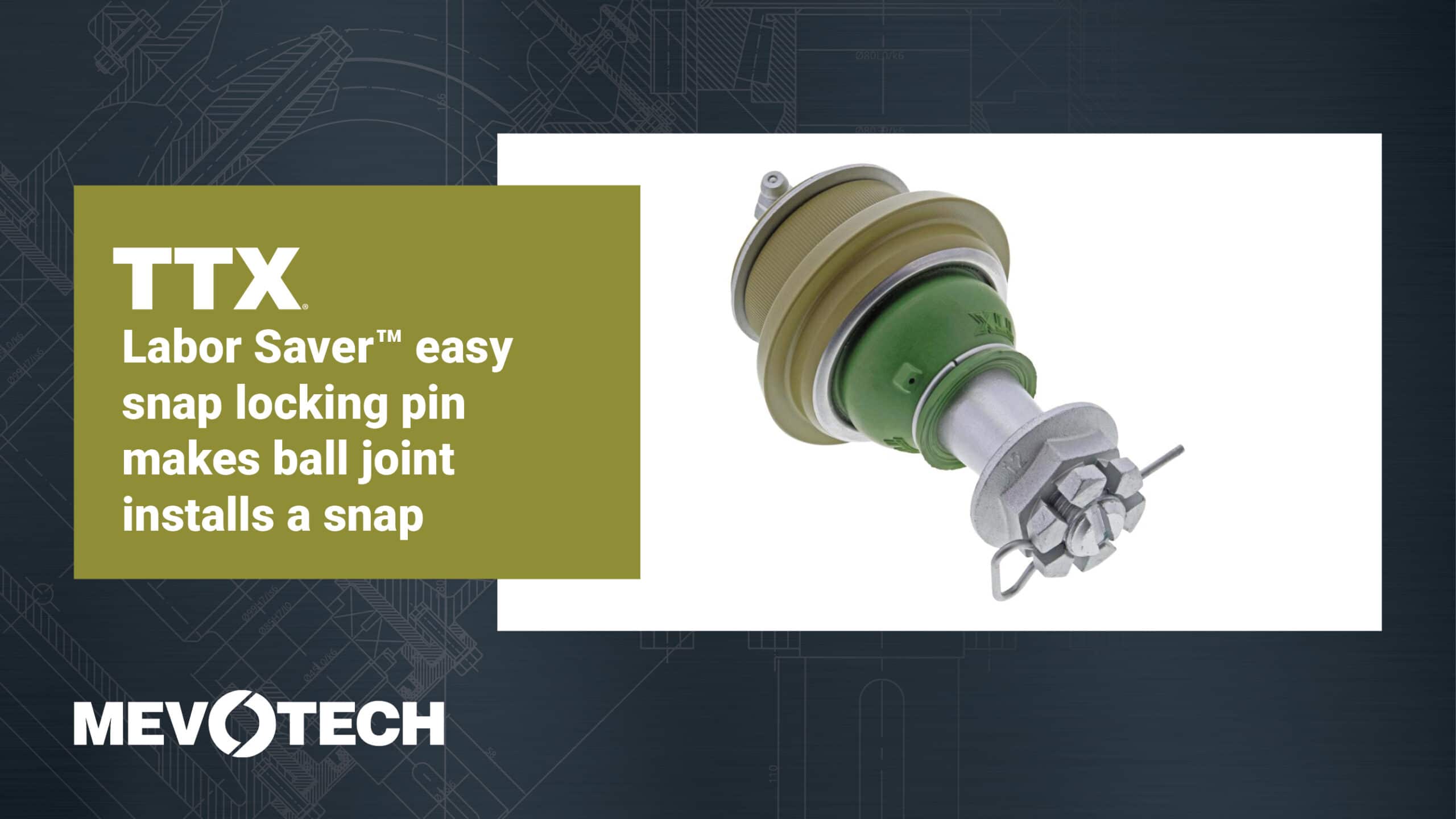

Supreme

Superior durability, tested endurance and unsurpassed quality. Ready to go right out of the box.

Original Grade

OE-Grade performance backed by design excellence. Restores performance, handling and ride.

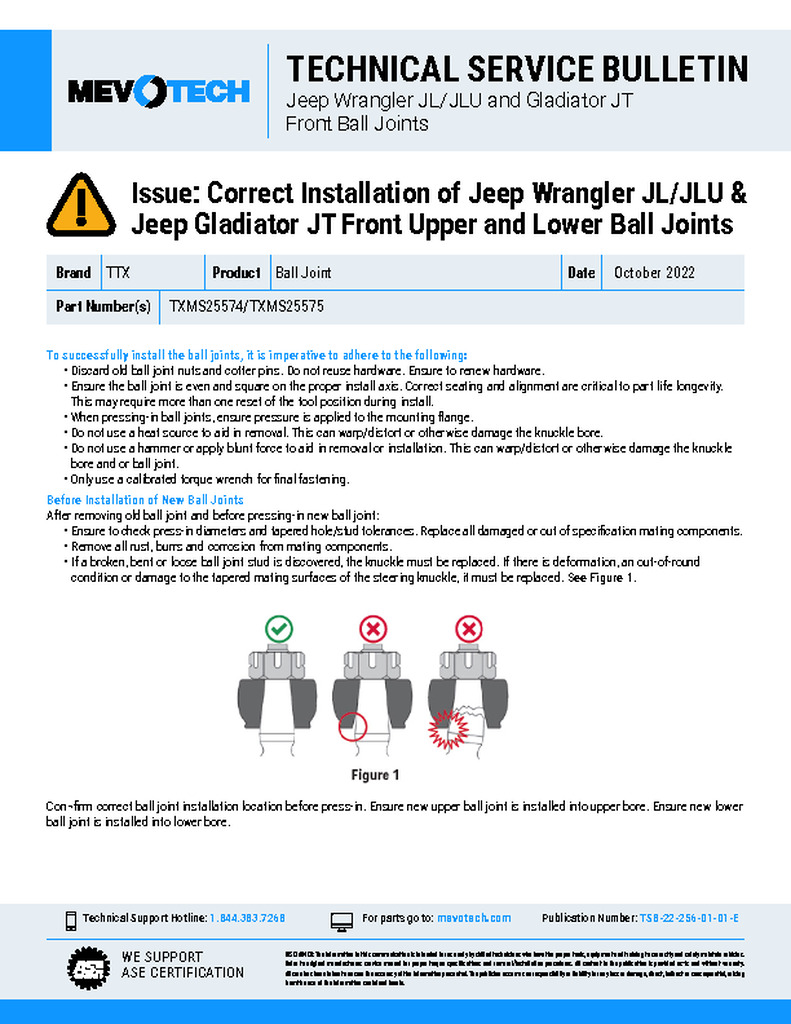

Why Are Control Arms Important?

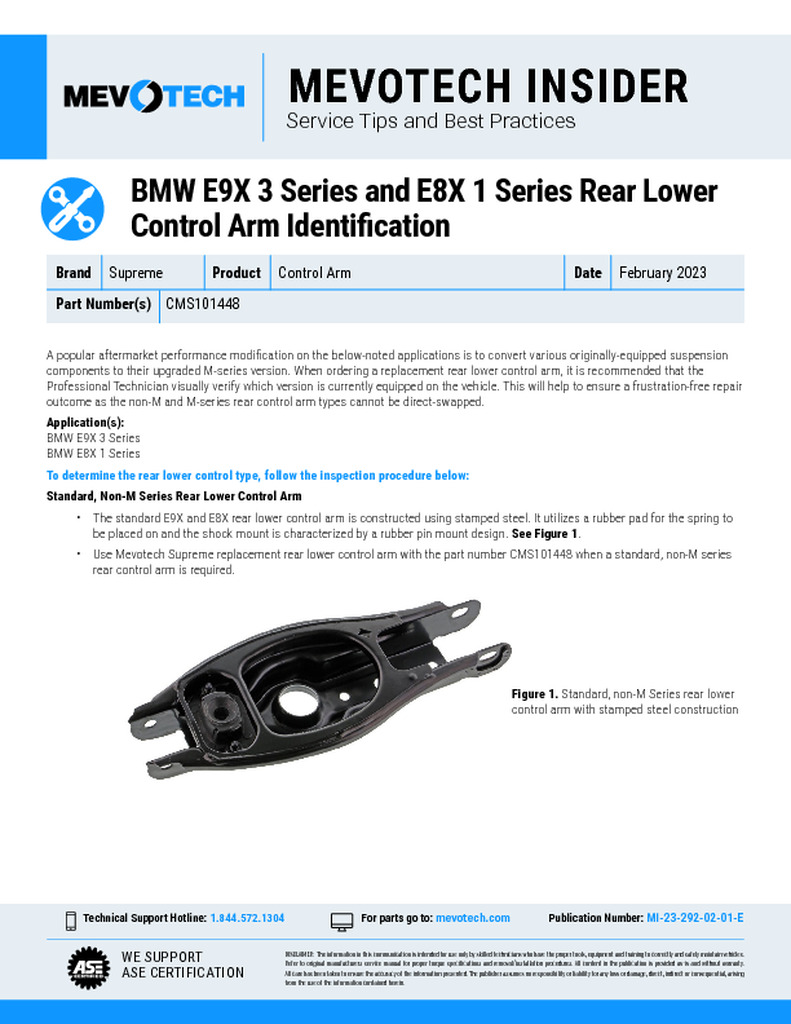

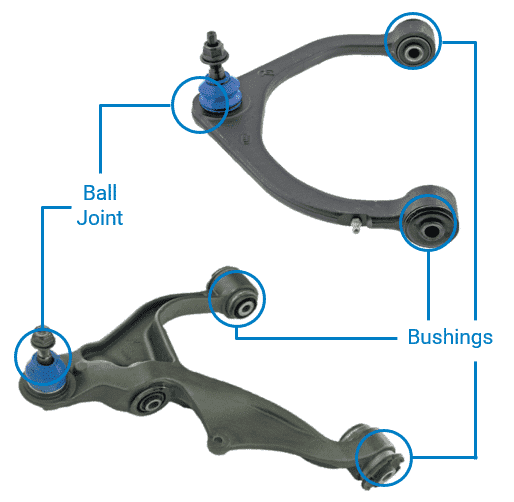

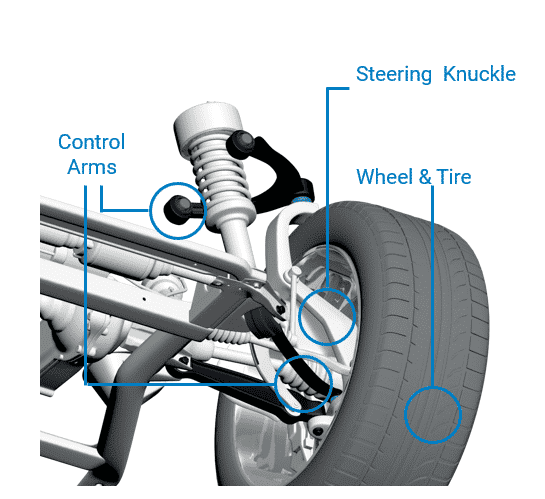

Control arms provide both a connection and pivot point between your vehicle’s suspension and chassis. Typically linking a steering knuckle to the body frame, control arms feature ball joints and bushings which work in tandem to retain correct wheel tracking and position. For example, a lower control arm assists in setting the longitudinal and lateral position of the wheel while the vehicle is in motion.

Control arms resist a multitude of loading forces, such as acceleration/braking, cornering while turning and the suspended weight of the vehicle body. They also have the additional function of maintaining dynamic wheel alignment. This reduces transmitted noise, road shock and vibration while providing resistance to unwanted suspension movement.

Depending on suspension configuration (Multi-Link, MacPherson, Double Wishbone), control arms can be located on the front and rear suspension, in both the upper and lower position.

By connecting the left and right suspensions of the vehicle to the stabilizer bar, stabilizer links maintain the wheels at the same height and reduce vehicle body roll.