Driven by Innovation

There are no limits. With 13 patented chassis technologies and over a thousand first-to-market exclusives, our innovations meet tough aftermarket challenges head on.

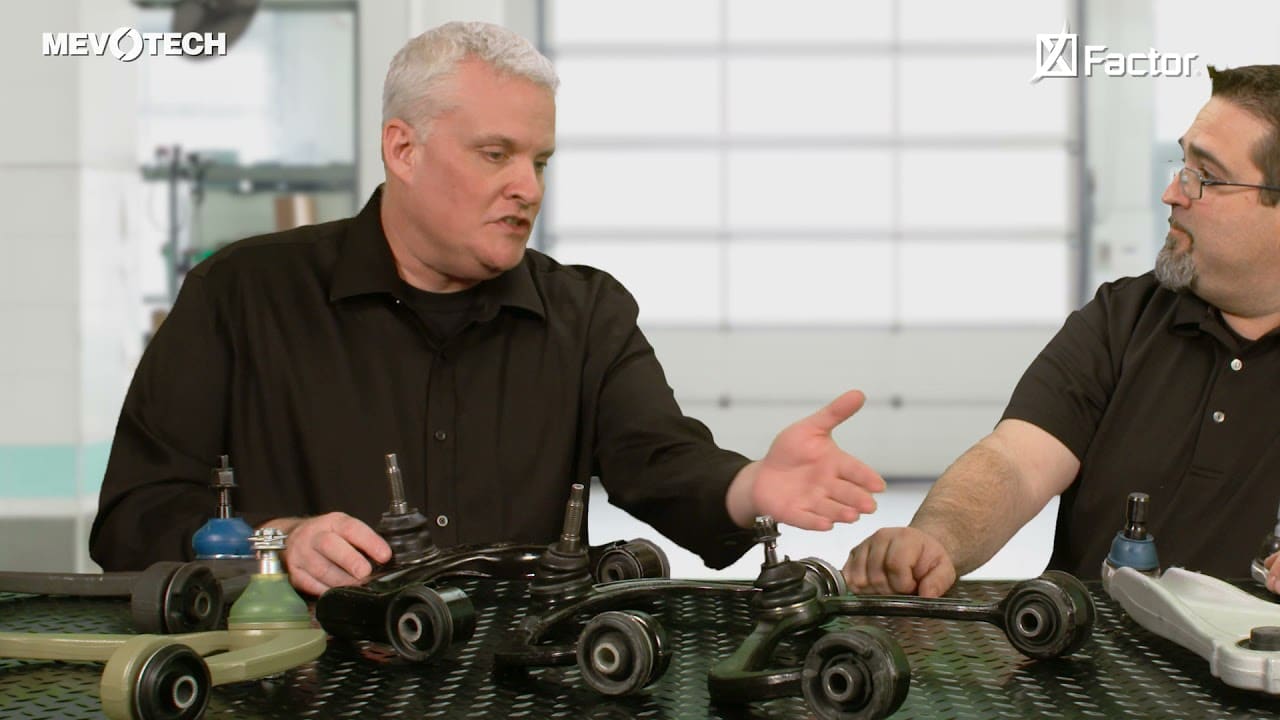

X-Factor High Performance Upgrades

Filter

- All

- Ball Joints

- Control Arms

- Stabilizer Links

- Tie Rod Ends

- Wheel Hub Assemblies

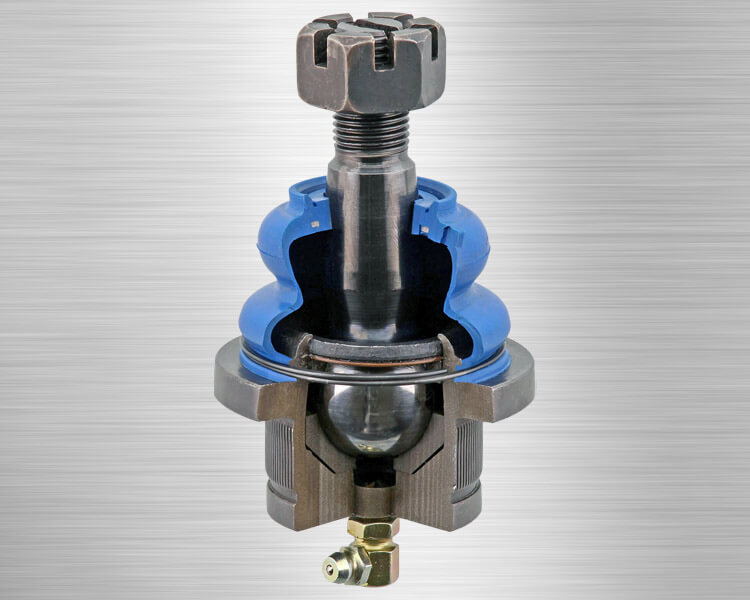

PWR-TEK Design

Upgrade to parts that can withstand extreme loading conditions with high-strength steel and larger bearings that are guaranteed not to deform.

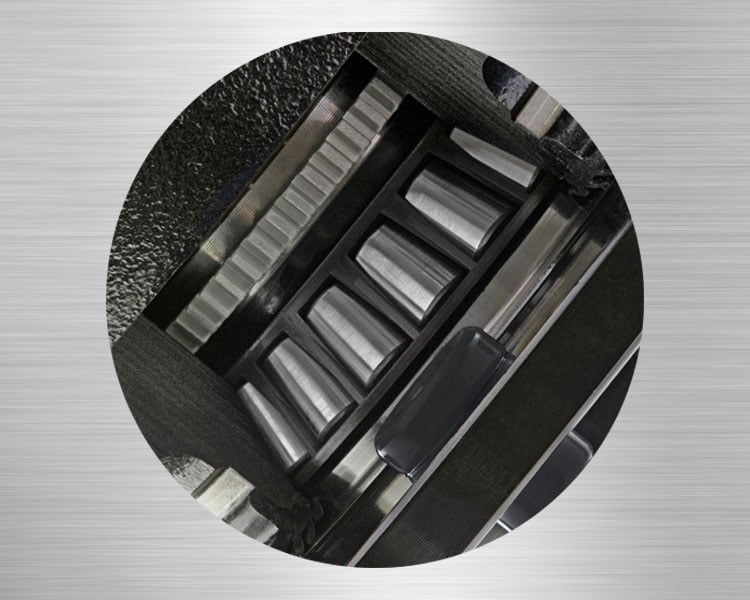

Engineered Internals

Precision-engineered higher grade rolling elements and optimized geometry to minimize rolling resistance and maximize load distribution.

Components are matched together for exact mating fitment – meaning quiet performance and longer service life.

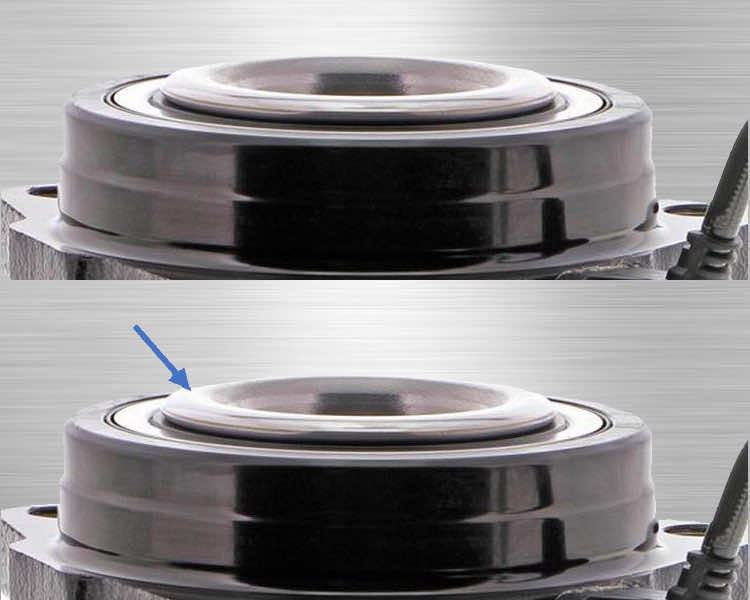

Generation 3 Orbital Roll Forming

Roll forming locks internal components for a set preload right out of the box. No adjustment is required over service life. Increased assembly stiffness reduces potential vibration and improves part life.

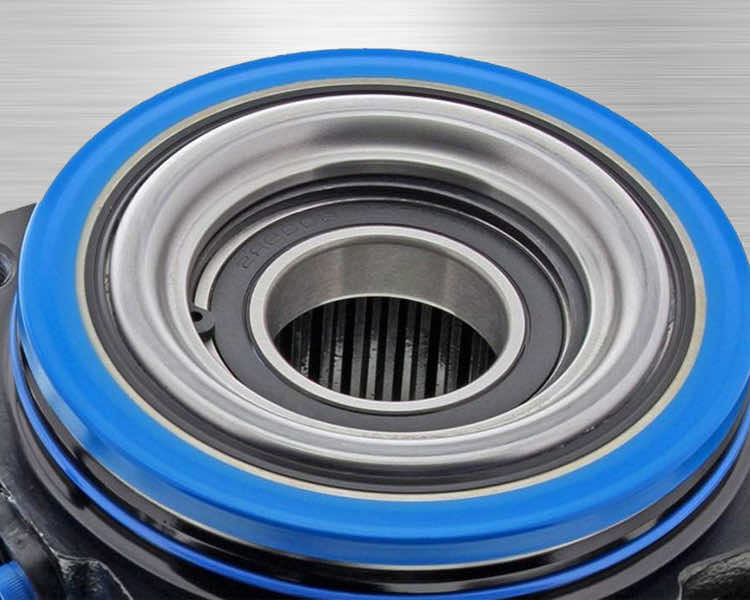

Advanced Sealing

Low-friction, heavy-duty Advanced Quantum Sealing System with a multi-lip profile that provides several layers of defense to keep contaminants out and vital grease in.

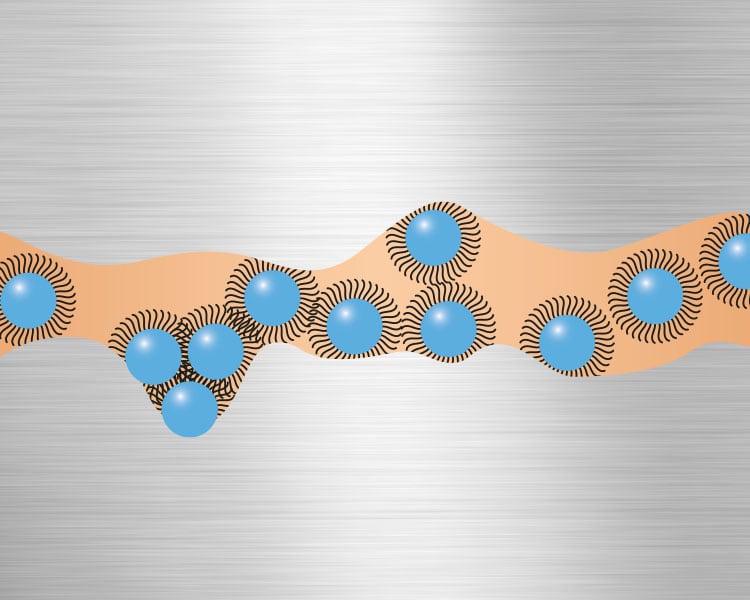

NanoCeramic Lubricant Technology

NanoCeramic lubricant withstands extreme temperatures, resists corrosion and washout, and retains viscosity.

Particles also act as microscopic bearings reducing friction, filling and smoothing out raceways and rolling elements.

Uninterrupted Wheel Speed Signal

A molded, thicker and abrasion-resistant cord guards against perforation and contaminants at both the sensor and plug ends to ensure a faultless signal for ABS, TCS and other vehicle safety systems. The sensors match to the original for type and output characteristics, meaning no interruption in this service.

Repel-TEK Anti-Corrosion

Repel-TEK™ anti-corrosion coating is applied to every surface, including studs and hardware, to prevent buildup and contaminant intrusion. This also makes removing associated components easier, like swapping wheels, replacing a CV shaft or a brake rotor.

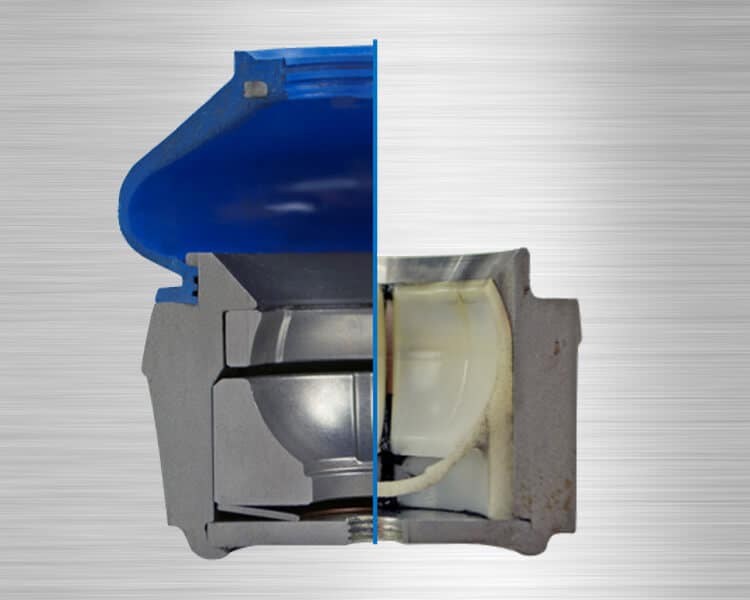

Sealed for Life

Lock out contaminants and keep vital grease in.

Precision Engineered

Enjoy a smoother ride with a flange design that reduces vibration when the vehicle is in motion.

Corrosion Protection

Anti-corrosion coating is applied to studs and hardware to protect components.

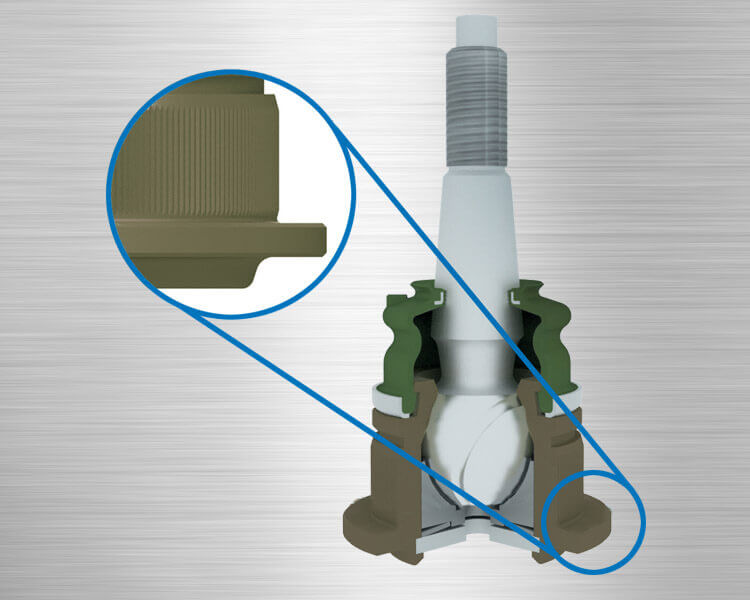

Knurled Housing

Precision engineered ridges for tighter grip between connecting components.

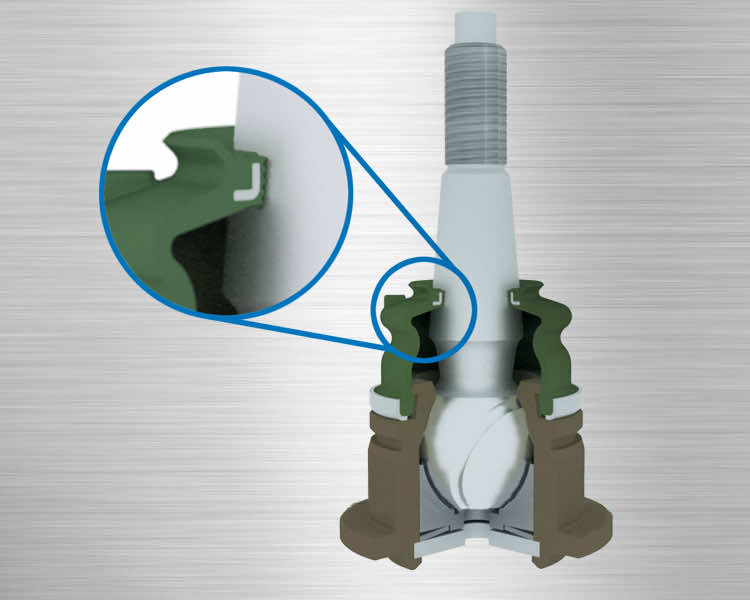

Locking Boot

Boot design permanently fixes boot to housing and creates perfect seal, keeping out contaminants.

Quad Sealing System

Additional lips on boot sealing surfaces prevent contaminants from entering into the boot.

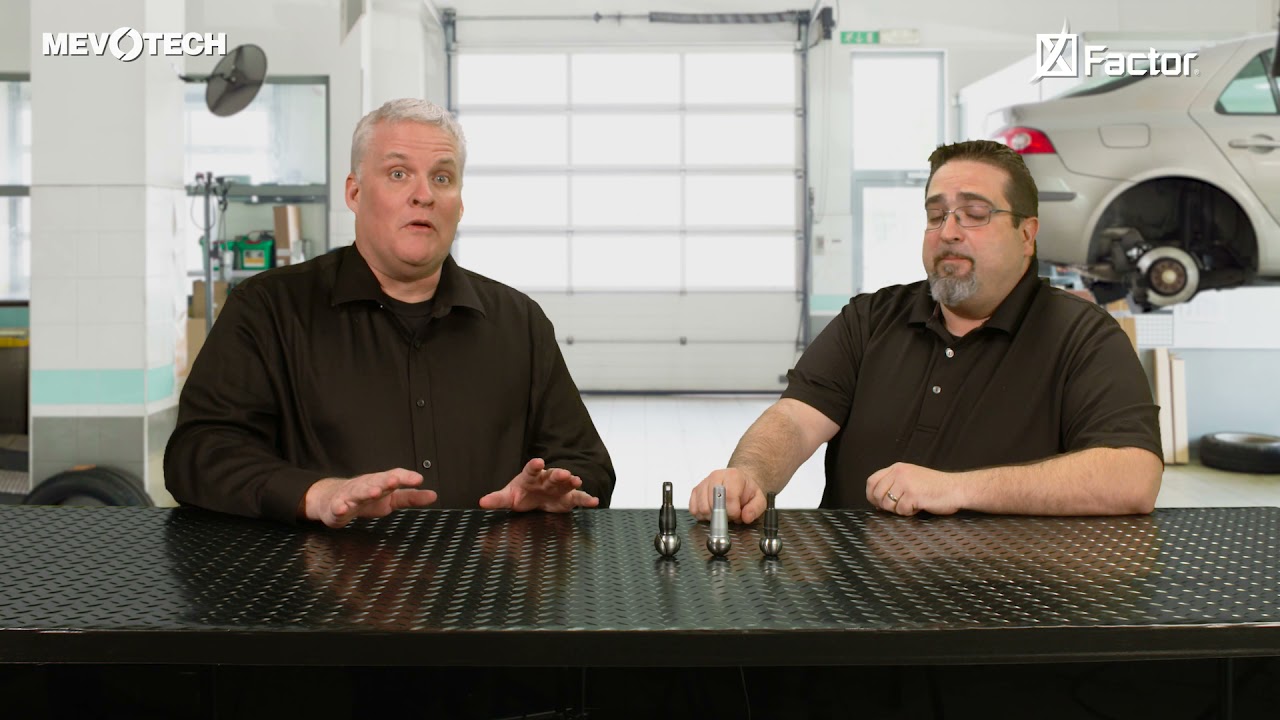

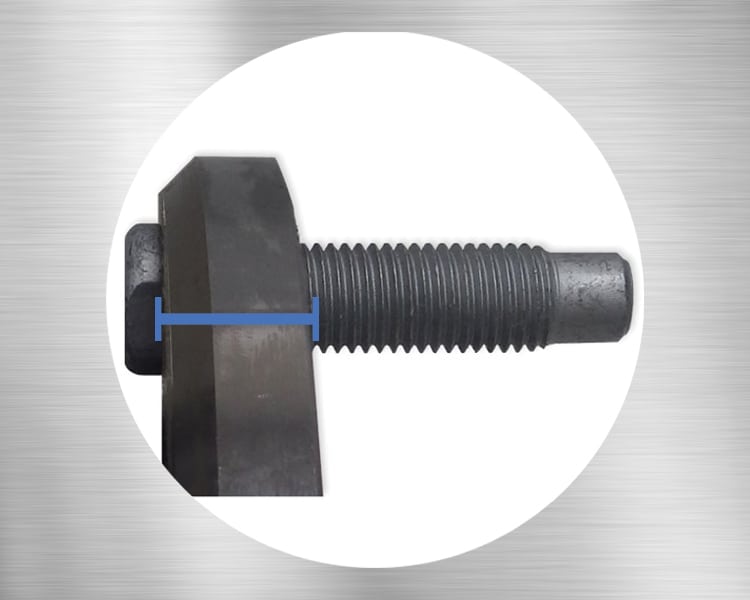

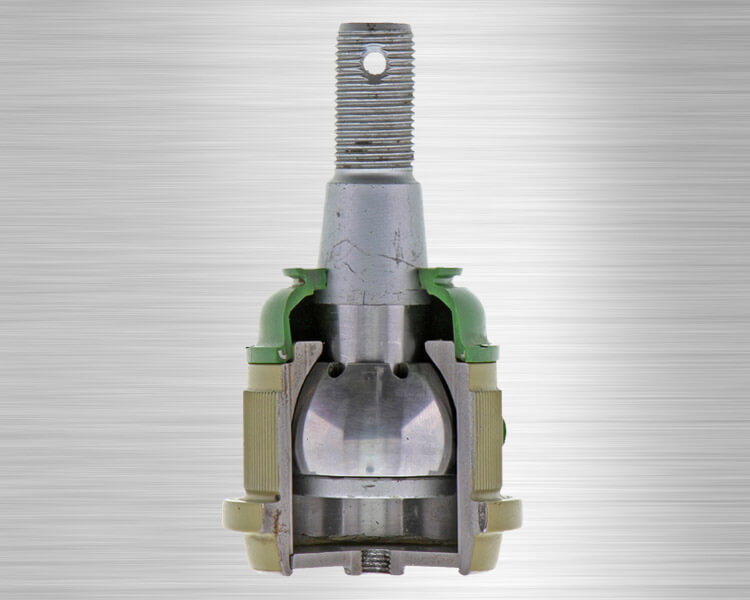

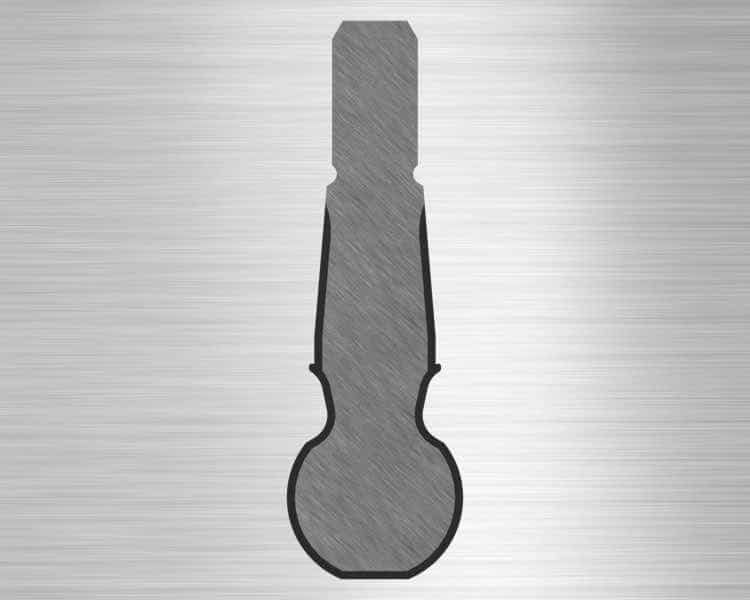

Increased Ball Stud Diameter

Increased sphere diameters improve contact pressure and durability of ball pin.

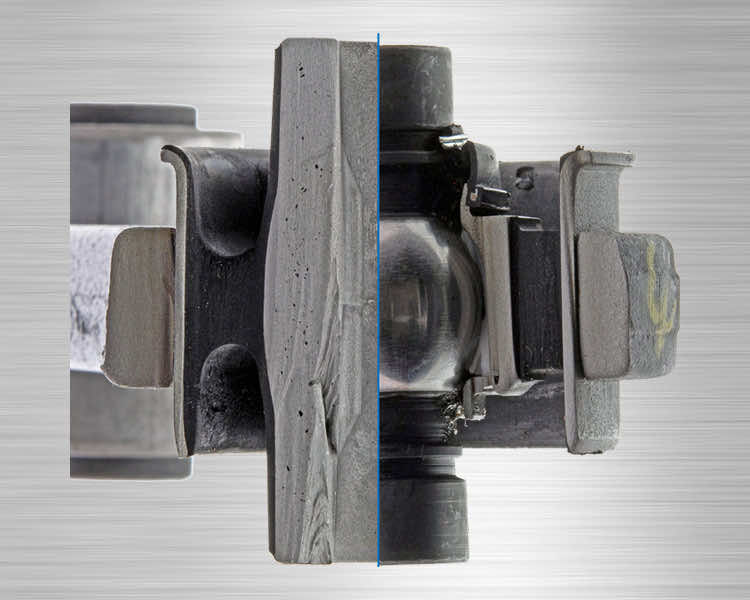

Larger/Thicker Housing Flanges

Provides additional strength and stiffness to the ball joint. Reduces the likelihood of deformation of the ball joint housing during installation. Facilitates the use of a wider range of ball joint installation tools.

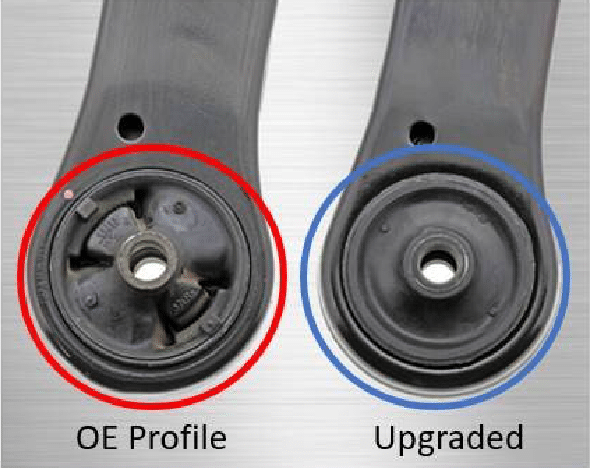

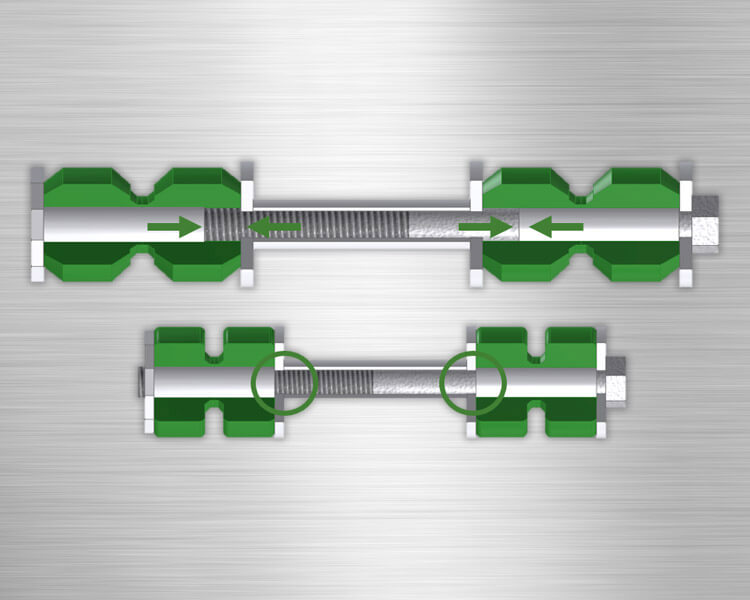

Upgraded Bushing Designs

Bushings are upgraded with filled in voids and/or additional rubber to improve the durability of the bushing.

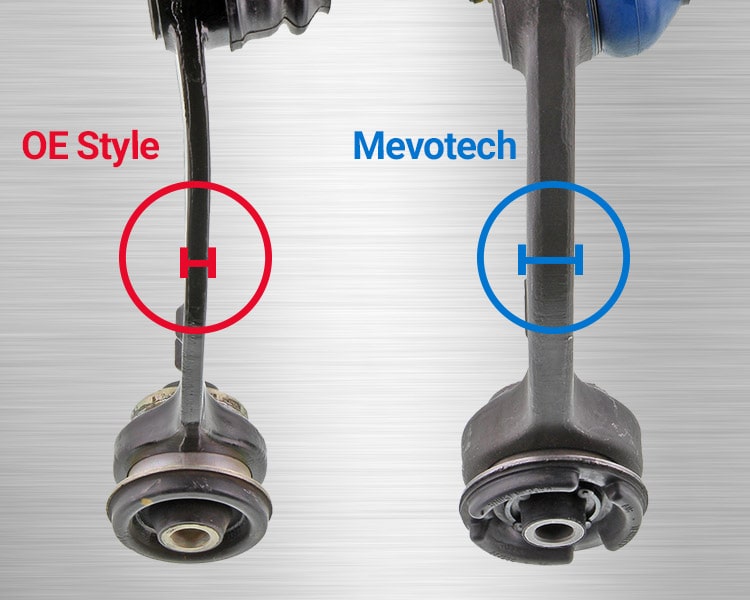

Enhanced Cross Sections

Additional material is added to the part to improve body stiffness and strength.

BiMetallic Control Arms

Exclusive patented (US no. 8757648) technology which allows for a ball joint featuring sintered metal bearings to be threaded into an unitized aluminum control arm.

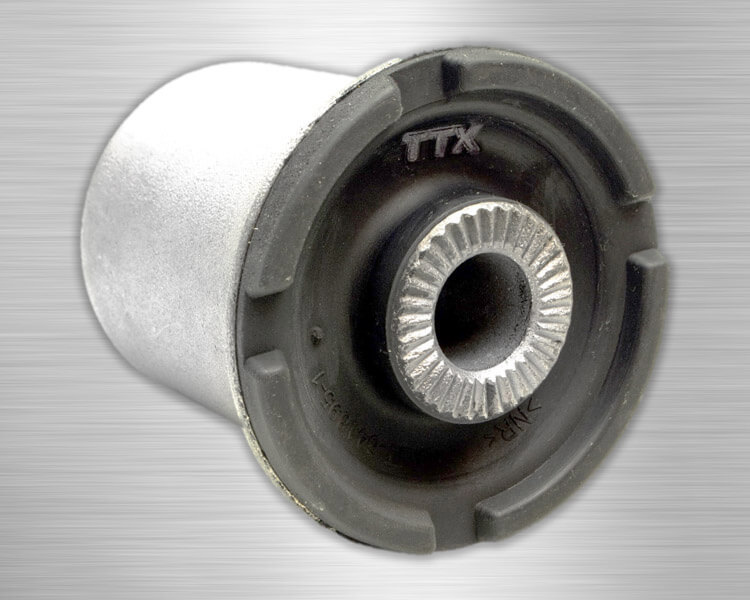

Bushing Radial Knurling

Bushing design with knurling on inner sleeve that assists to secure the bushing to the frame.

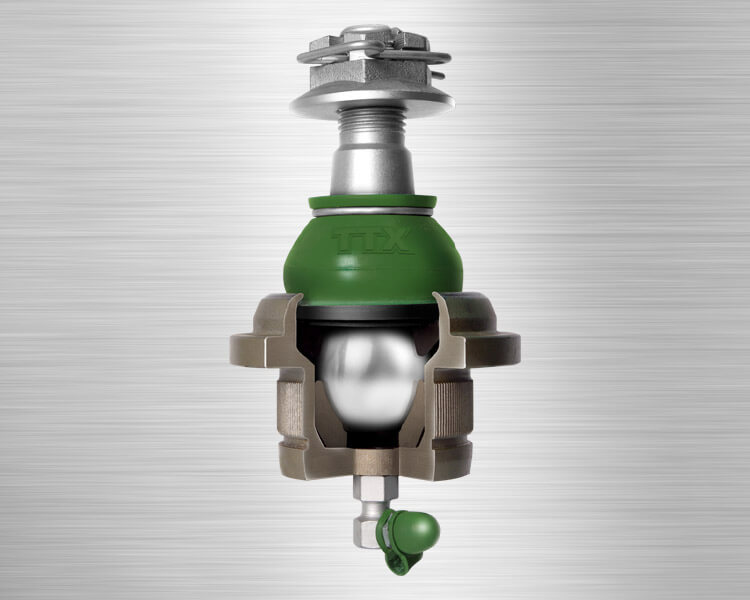

Greaseable Ball Joints

Ball Joint is serviceable allowing the user to continue to grease the ball joint improving the service life of the ball joint.

Sintered Metal Bearings

Bearings made of a durable sintered powder metal that leads to a longer lasting part.

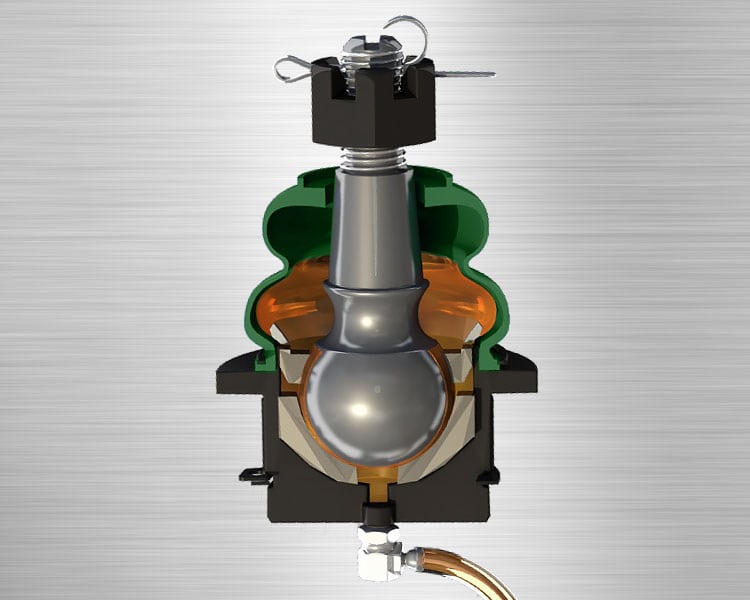

Patented Snap-In Bearing

Oversized sintered metal bearing with large contact area is engineered to accommodate challenges of a worn knuckle.

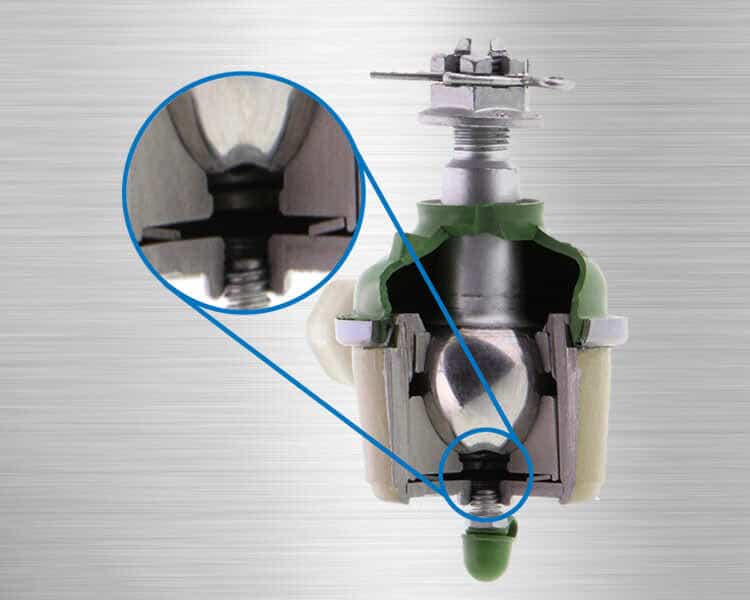

Self-Sealing Grease Relief

Grease relief that acts like a one-way valve allowing excess grease to flow out of the boot while preventing contaminants entering the boot.

REPEL-TEK™ Coatings

Corrosion resistant coatings that prevent the formation of rust for a longer part service life.

Integri-Boot™

Boot is mechanically locked in place by the housing lamination preventing contaminants from entering the boot.

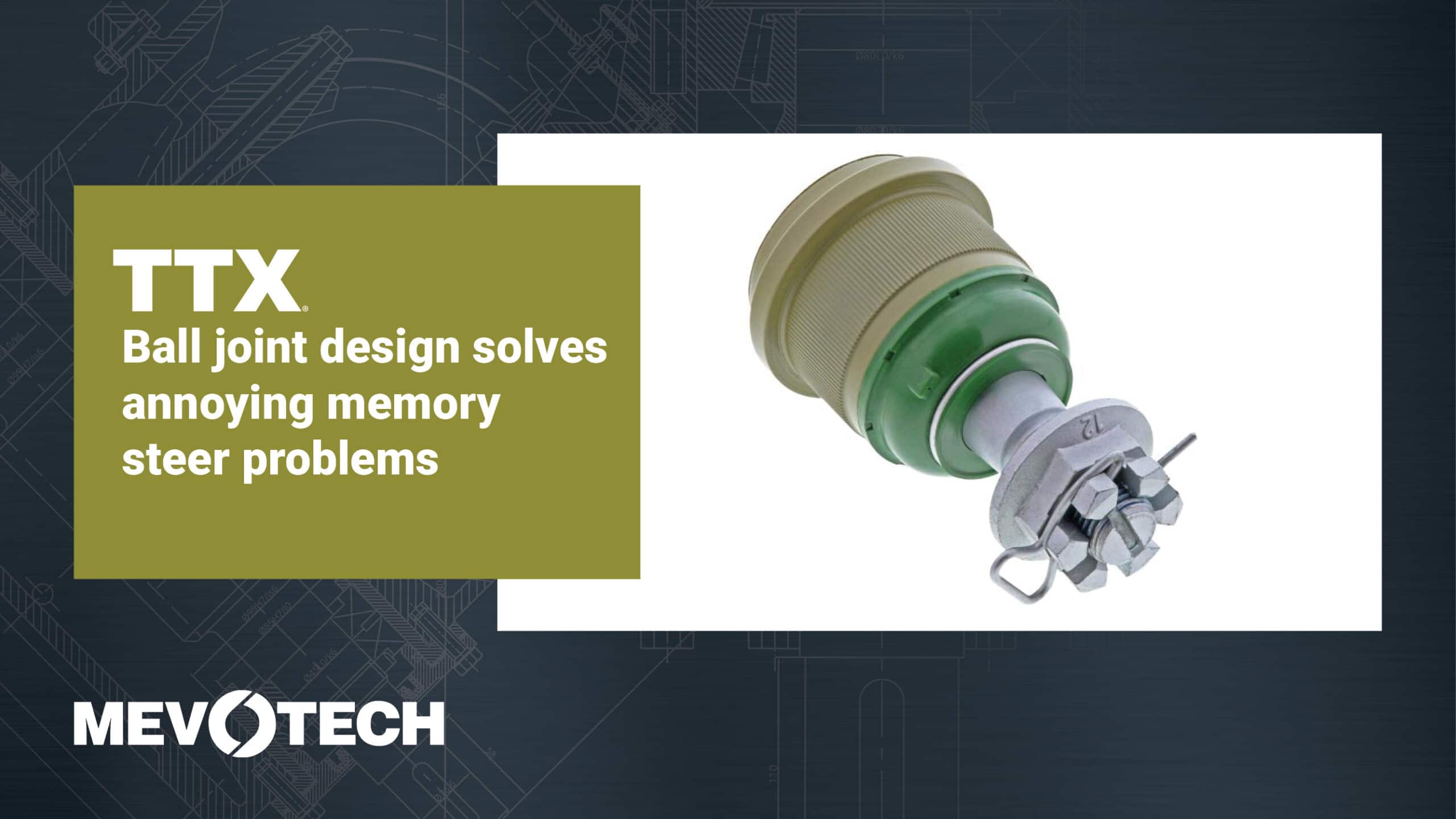

Optimized Compression Control (OCC) Design

Designed to prevent over-compression of bushings during installation which extends the service life of the bushing.

Patented Stepped Bearings

Engineered bearings designed with a recess that prevent flattening of the Belleville spring washer which leads to an increased service life of the ball joint.

Anti-Corrosion Coatings

Corrosion resistant coatings that prevent the formation of rust for a longer part service life.

Circlip

Secure the ball joint with the circlip included to provide supplementary retention for the ball joint housing, locking it into place.

Patented Directional Bearing

Allows for proper implementation of upper bearing on ball joints with larger swing angle in one direction. Addition of upper bearing provides additional contact area and greater pressure distribution for less wear.

Higher Grade Hardware

Hardware provided is made with a high grade and strength.

Premium Grease

Ball Joint is provided with premium grease that leads to an improved ball joint life.

Ball Pin Surface Hardening

Ball Pins are surface hardened to prevent premature wear and improve fatigue life

Upgraded Spherical Bushing

Bushings are upgraded from Rubber to Spherical Bushings.

Upgraded Seals

Get a longer service life with upgraded seal material that provides an increased barrier to water and contaminants.

Roll Formed Assemblies

Increases rigidity and stiffness vs. interference fit design. Holds internal settings more consistently than the press fit design. Reduces load on components and associated part failure. Can limit potential damage and deformation arising from an over torque condition.

Larger/Thicker Housing Flanges

Provides additional strength and stiffness to the ball joint. Reduces the likelihood of deformation of the ball joint housing during installation. Facilitates the use of a wider range of ball joint installation tools.

Anti-Rotation Features

Parts engineered with anti-rotation features that speed up and give piece of mind during installation.

Longer Wrench Flats

Tie rods designed with longer wrench flats that provide a larger area for using a wrench which eases installation.