Search parts

-

Year

Make

Model

Sub Model - Drive Type

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1999

- 1998

- 1997

- 1996

- 1995

- 1994

- 1993

- 1992

- 1991

- 1990

- 1989

- 1988

- 1987

- 1986

- 1985

- 1984

- 1983

- 1982

- 1981

- 1980

- 1979

- 1978

- 1977

- 1976

- 1975

- 1974

- 1973

- 1972

- 1971

- 1970

- 1969

- 1968

- 1967

- 1966

- 1965

- 1964

- 1963

- 1962

- 1961

- 1960

- 1959

- 1958

- 1957

- 1956

- 1955

- 1954

- 1953

- 1952

- 1951

- 1950

- 1949

- 1948

- 1947

- 1946

- 1945

- 1944

- 1943

- 1942

- 1941

- 1940

- 1939

- 1938

- 1937

- 1936

- 1935

-

Results For

-

-

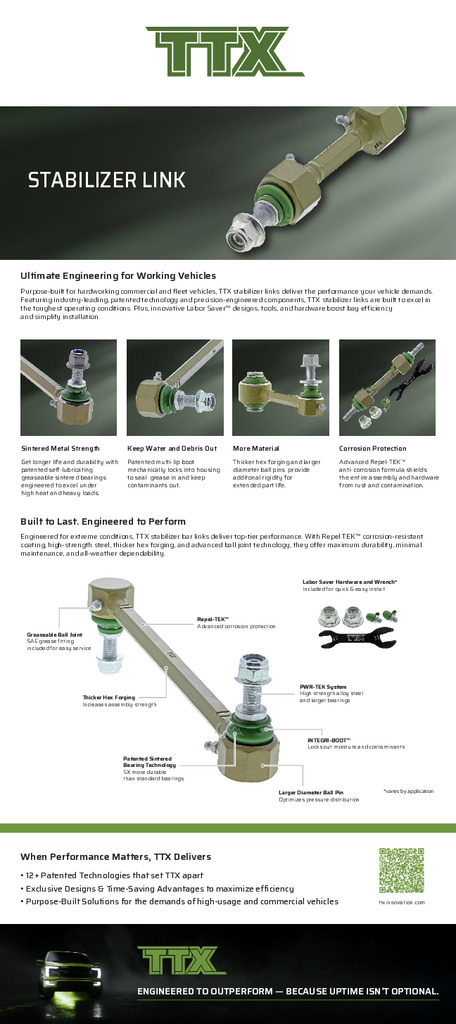

STABILIZER LINKS

BUILT TO CONTROL BODY ROLL

ENGINEERED FOR TECHNICIANS

Enhanced body. Increased stiffness.

Reduces vibration to restore a smooth, easy ride.

Driven by Innovation

There are no limits. With 12 patented chassis technologies and over a thousand first-to-market exclusives, our innovations meet tough aftermarket challenges head on.

Rigorous Testing

Extensive in-house and third-party durability testing ensures ultimate performance and strength.

Engineering you can count on for a smooth ride.

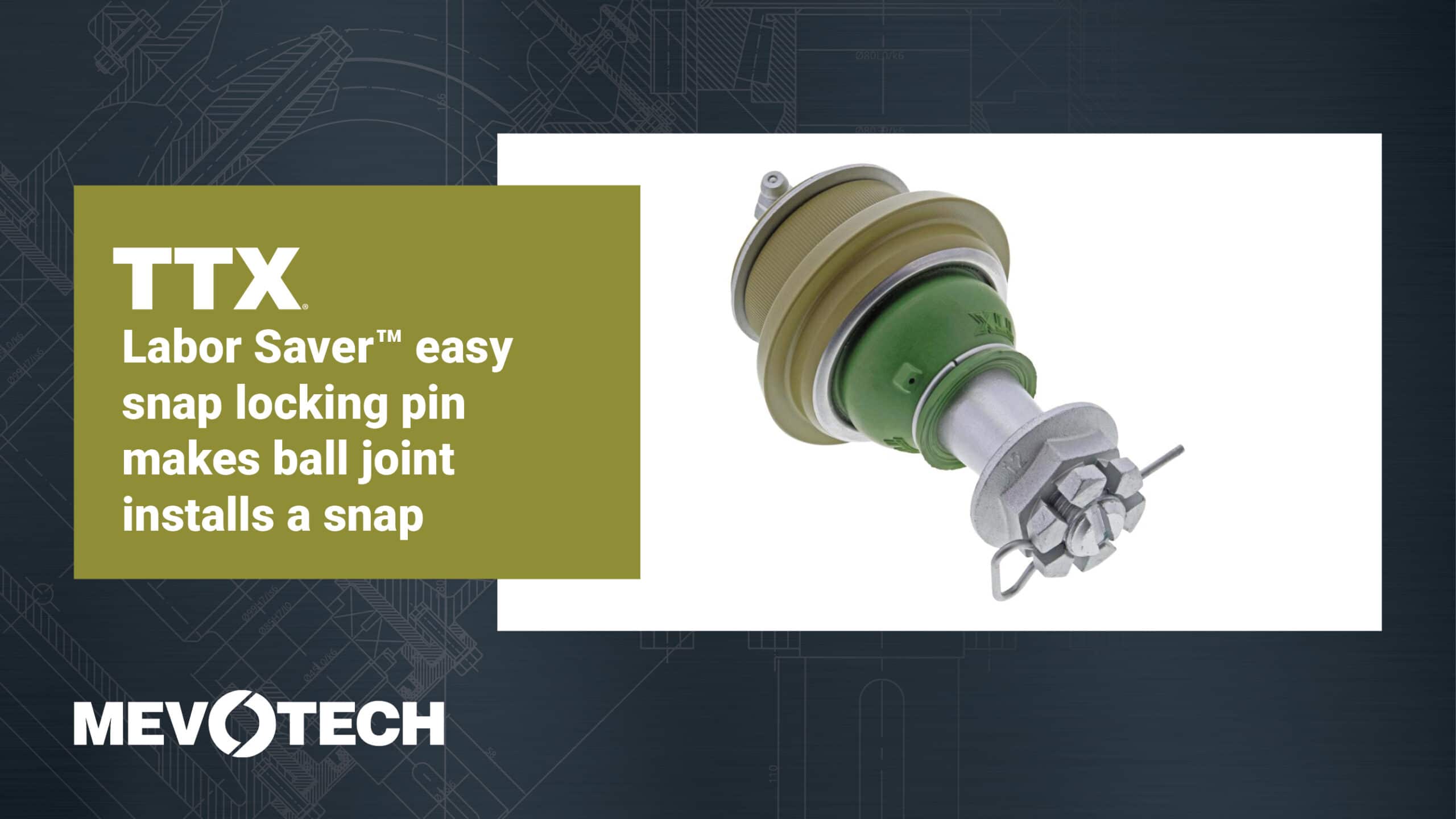

Supreme

Superior durability, tested endurance and unsurpassed quality. Ready to go right out of the box.

Original Grade

OE-Grade performance backed by design excellence. Restores performance, handling and ride.

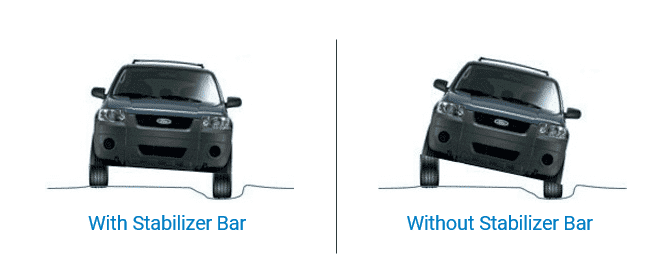

Why Are Stabilizer Links Important?

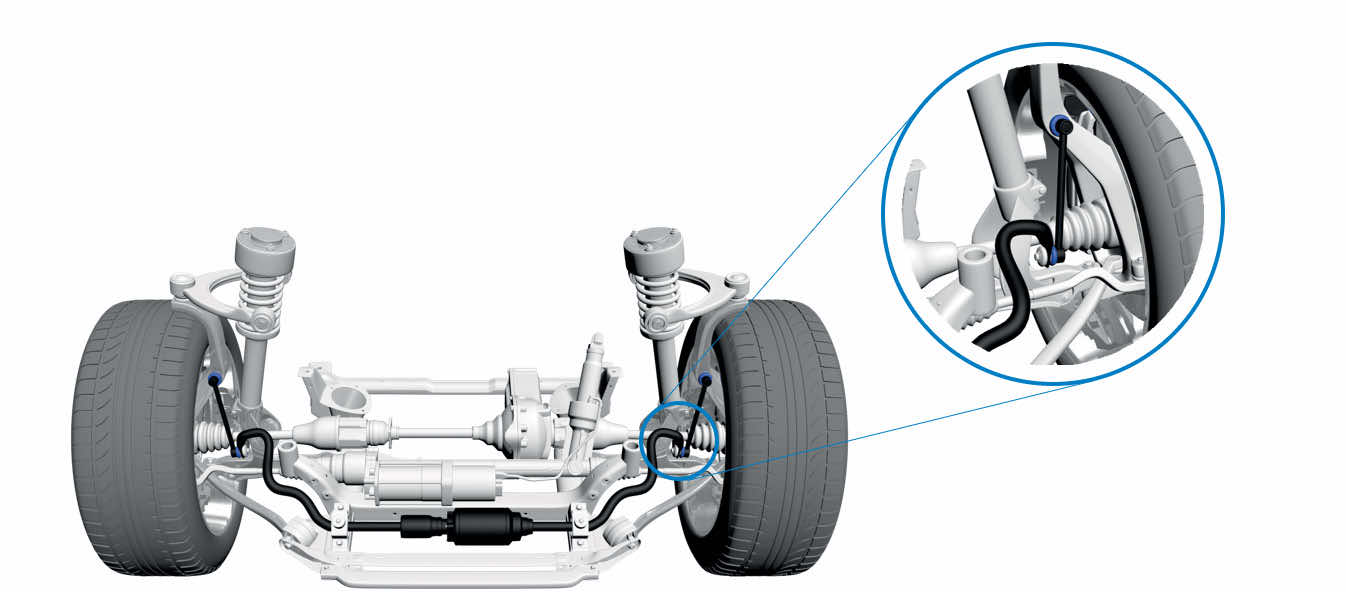

In conjunction with a stabilizer bar and stabilizer bushings, stabilizer links reduce your vehicle’s body roll by transferring lateral force to the opposing side during a corner or turn. Typically, one end of the stabilizer link is mounted to the stabilizer bar, while the other is connected to a suspension component on the wheel side.

A stabilizer link connects both the left and right suspensions to the stabilizer bar.

By connecting the left and right suspensions of the vehicle to the stabilizer bar, stabilizer links maintain the wheels at the same height and reduce vehicle body roll.