Downtime Is the New Disruptor: Why Specialized Parts Are the Next Competitive Advantage

In today’s automotive repair landscape—whether it’s cars, trucks, or fleet vehicles—bay efficiency is no longer a goal, it’s a survival strategy.

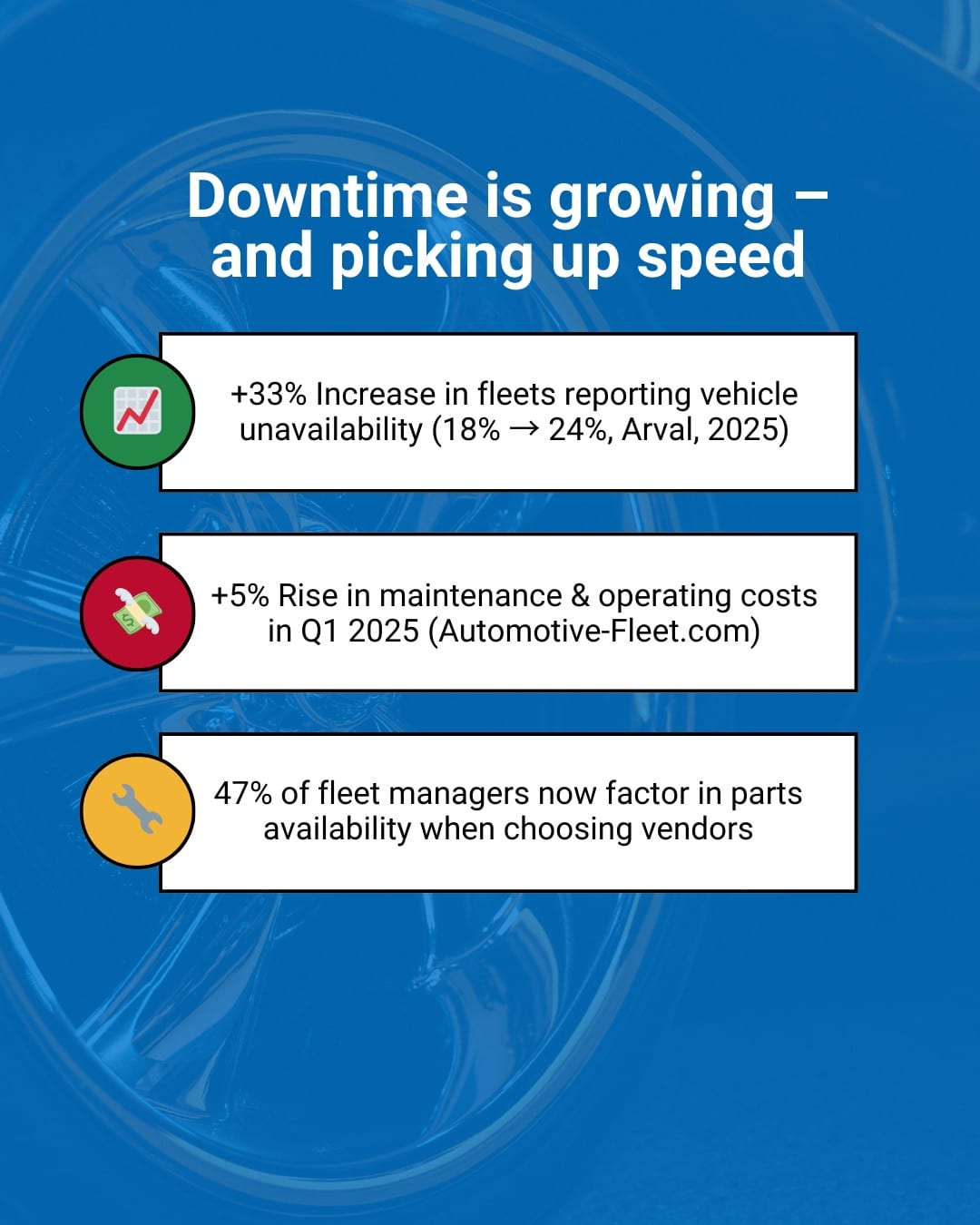

Vehicle downtime is rising, and it’s hitting where it hurts: on the balance sheet and in lost productivity. According to the 2025 Arval Mobility Observatory (BodyShopMag), the number of fleets reporting service-related vehicle unavailability rose by nearly a third year-over-year, from 18% to 24%. From aging vehicles and technician shortages to supply chain slowdowns, repair timelines are stretching—and the pressure is compounding.

The result? Shops are not just buying parts; they’re buying availability, reliability, install speed, and long-term efficiency.

The Hidden Cost of Downtime

This isn’t just about waiting a few extra days for a component. Every hour a vehicle is off the road has a cascading impact.

A recent report from @ Automotive Fleet found that maintenance and operating costs rose 5% in Q1 of 2025 alone, driven by extended vehicle lifecycles, inflation, and labor strain (Automotive-Fleet.com).

Meanwhile, nearly 47% of fleet managers now consider parts availability and service efficiency as top decision factors when selecting service centers they can rely on. It’s not just about specs anymore—it’s about minimizing risk and maximizing uptime.

Smarter Parts for a Tougher Landscape

This is where technician-first innovation becomes critical. It’s not just about part strength—it’s about how the component performs under stress, how it installs in real-world conditions, and helps keep vehicles on the road longer.

Here’s what’s defining the next generation of premium parts and how Mevotech chooses to standup and standout in the market:

- Purpose-built parts to withstand high-mileage environments

- Comprehensive installation kits—packed with everything a technician needs including Labor Saver™ components to streamline workflow

- Purpose-built for the aftermarket, our parts are designed to adapt to the needs of on-the-road vehicles, delivering consistent fitment that minimizes frustration and reduces costly rework.

We call this being #WrenchReady. It’s the difference between a part that fits on paper, and one that actually works in the bay—under time pressure, in extreme conditions, and in the hands of the people doing the tough work.

From Technician to Service Manager to Jobber: Value That Scales

Across the value chain, smarter parts translate into real business outcomes:

- Technicians save time with purpose-built install-friendly engineering

- Shops benefit from faster turnaround and reduced comebacks

- Distributors gain easier access to First to Market parts along with training and support for technicians and counter staff

- Fleets see higher uptime and lower total cost of ownership

The Road Ahead

Downtime is no longer an inconvenience—it’s a business disruptor. That’s why we engineer technician-first solutions, backed by proactive inventory and innovative product design. From chassis to hubs to brakes, every component is built to install faster, last longer, and perform when it matters most.

Because real-world conditions don’t wait for perfect timing—and neither should your parts.