DRIVE ALONG: TWO GUYS, A HYBRID JEEP® AND TTX™ PARTS

Mevotech Territory Manager, Barry Sullivan, and Technical Sales Manager, Austin Loomis, recently took to the road in a 2022 Jeep Wrangler Rubicon 4XE. The two were testing out Jeep’s first hybrid, in a drive-along discussion about the axle system. Along the way, they talked about how the vehicle needs chassis parts that can handle extreme forces, both from the modifications Jeep owners love and the instant torque that the 4XE’s two electric motors provide (in addition to the turbocharged I-4 gas engine).

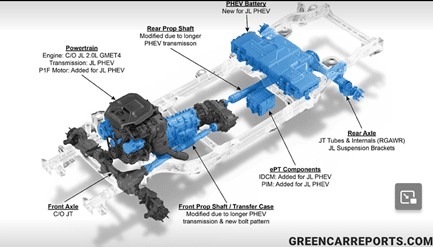

With its hybrid system plumbed through the powertrain (left), the 4XE still has the original Jeep advantage of front and back solid axles for great off-road performance. Austin commented, “This really narrows it down to using a knuckle and ball joints, as well as a hub and other parts, to make the whole suspension system work. It basically has strut rods and a track rod, and then it has a long tie rod steering system, just like any other Jeep would.”

With its hybrid system plumbed through the powertrain (left), the 4XE still has the original Jeep advantage of front and back solid axles for great off-road performance. Austin commented, “This really narrows it down to using a knuckle and ball joints, as well as a hub and other parts, to make the whole suspension system work. It basically has strut rods and a track rod, and then it has a long tie rod steering system, just like any other Jeep would.”

He continued, “That’s kind of the beauty of it – it’s still the simple Jeep platform but it’s just integrated with a hybrid powertrain now.”

While driving the 4XE both on-road and off, the conversation turned to how Mevotech’s premium TTX™ brand provides superior driveline, steering, suspension and hub assembly components engineered for the kind of action these Jeeps face every day. No matter the vehicle, it’s important to equip it with parts that are built for durability and a long service life. Austin talked about touring shops and seeing cracked rims, bent control arms and more, just from people driving at normal speeds on rough winter roads. While Barry has seen enough Canadian winters to know just how damaging salt can be. Fortunately, tough TTX™ parts are engineered with upgrades for lasting durability and performance. Plus, the thick Repel-Tek™ coating helps guard against damaging rust and corrosion.

When Modifications Are Added to the Mix

Anyone who drives a Jeep knows that modifications are an important part of the Jeep culture and experience, but modifications bring their own set of complications. Lifted vehicles and altered suspensions change the vehicle’s geometry and affect the loading in the steering and suspension systems. This can cause accelerated failure in parts like ball joints, control arms, and stabilizer bars and links. The vehicle Austin and Barry drove had big, meaty tires, which can increase grip but also put even more force on the suspension and chassis parts. So, it’s important to choose parts that come with upgraded materials, stronger components and bulkier cross sections.

Dealing with the Added Weight of a Hybrid

The Rubicon hybrid is carrying approximately an extra thousand pounds because of the 4XE system, so braking and cornering applies a lot more force on the wheels, suspension and chassis. The instant torque of the electric motors adds even more punishment, as bushings and ball joints, etc., are forced into immediate action.

Big, Heavy Hybrids and Modified Suspensions Need Tougher, Beefier Parts

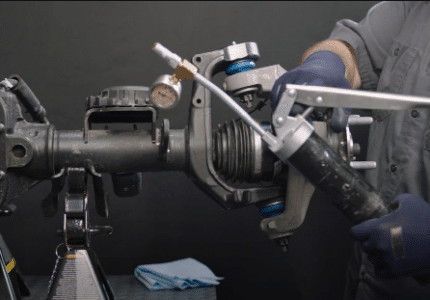

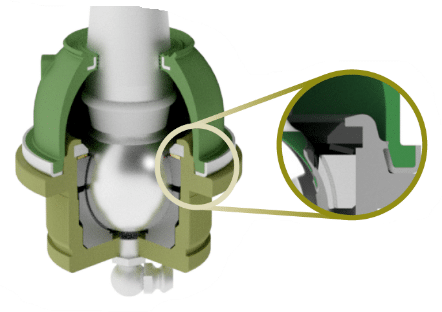

Parts that see the most wear, like ball joints, need to be built strong, but CAFE restrictions mean the OE needs to light-weight components. TTX™ ball joints aren’t held to the same restrictions, and the ones for the 4XE feature a whole host of X-Factor upgrades, including sintered metal bearings (left), which are self-lubricating, greasable and stand up to heat and wear much better than the OE plastic bearing.

Parts that see the most wear, like ball joints, need to be built strong, but CAFE restrictions mean the OE needs to light-weight components. TTX™ ball joints aren’t held to the same restrictions, and the ones for the 4XE feature a whole host of X-Factor upgrades, including sintered metal bearings (left), which are self-lubricating, greasable and stand up to heat and wear much better than the OE plastic bearing.

Additionally, the patented, high strength multi-lip boot (right) mechanically locks into the housing to protect the ball joint internals from contaminants while the Repel-Tek™ coating provides an enduring barrier to rust.

The solid front axles on these Jeeps mean that the ball joints must be ready to see a lot of action. Every time the wheel is turned or a bump is hit the ball joints are going to be under pressure to perform. That’s why TTX™ has taken that extra step to create a bearing material proven to last much longer. It’s basically a powdered metal that has been put through a sintering process, to create a very durable bearing material that the ball sits on inside the ball joint. The OE bearing, as mentioned, is plastic and if the ball hits that all day it’s bound to wear out quickly. TTX™ sintered metal technology can take more load, more force and just provide more durability overall.

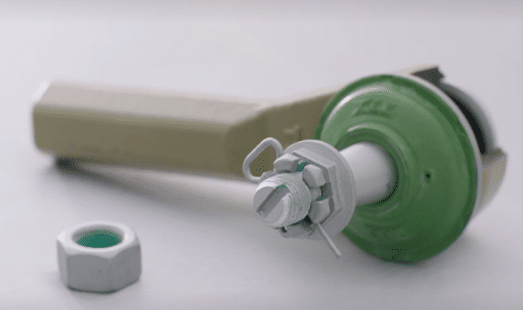

While driving along, Austin and Barry zeroed in on the fact that outer tie rod ends (left) are among the first parts to wear out, especially if you’re putting bigger wheels and tires on vehicles like Jeeps. While the OE design is usually just a smooth tie rod end with plastic on the inside, the TTX™ version has all the other upgrades of a TTX™ ball joint, like better boot technology, sintered bearings and Repel-Tek™ corrosion protection. And even the hardware is grade 12 and silver coated to completely eliminate any chance of rust.

While driving along, Austin and Barry zeroed in on the fact that outer tie rod ends (left) are among the first parts to wear out, especially if you’re putting bigger wheels and tires on vehicles like Jeeps. While the OE design is usually just a smooth tie rod end with plastic on the inside, the TTX™ version has all the other upgrades of a TTX™ ball joint, like better boot technology, sintered bearings and Repel-Tek™ corrosion protection. And even the hardware is grade 12 and silver coated to completely eliminate any chance of rust.

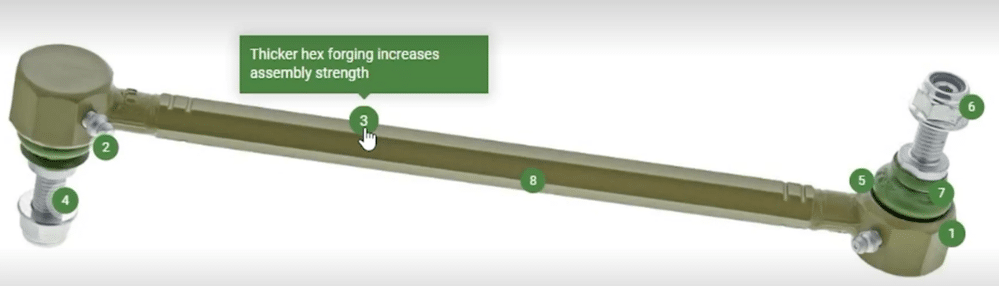

They also talked about how Mevotech engineers take aftermarket parts up a notch, by considering ease of installation, in addition to service life. For example, TTX™ stabilizer links (above) for the 2022 Rubicon 4XE have hex-forging to make them more durable, as well as being easier to grip with a wrench during installation. The stabilizer links also come with those upgraded ball joints with sintered bearings and multi-lip sealing boots for high durability and performance.

They also talked about how Mevotech engineers take aftermarket parts up a notch, by considering ease of installation, in addition to service life. For example, TTX™ stabilizer links (above) for the 2022 Rubicon 4XE have hex-forging to make them more durable, as well as being easier to grip with a wrench during installation. The stabilizer links also come with those upgraded ball joints with sintered bearings and multi-lip sealing boots for high durability and performance.

Summary

Jeeps are so iconic that people have formed communities around them. With the number of Jeeps being sold, the VIN registry is off the chart – and it’s not slowing down. The beauty of the 4XE is that it has the efficiency of a hybrid but it can still be modified, Jeep-style. Additionally, these SUVs are used for working vehicles, like first responders, which can’t afford downtime.

To keep these big, heavy and often modified hybrids running smoothly, the right aftermarket parts are needed. Whether it’s sintered metal technology, bigger ball pins, tougher coatings or beefier parts overall, TTX™ was made for the punishment that Jeeps are known to endure. Watch Austin and Barry in action in the Drive Along videos.