Search parts

-

Year

Make

Model

Sub Model - Drive Type

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2011

- 2010

- 2009

- 2008

- 2007

- 2006

- 2005

- 2004

- 2003

- 2002

- 2001

- 2000

- 1999

- 1998

- 1997

- 1996

- 1995

- 1994

- 1993

- 1992

- 1991

- 1990

- 1989

- 1988

- 1987

- 1986

- 1985

- 1984

- 1983

- 1982

- 1981

- 1980

- 1979

- 1978

- 1977

- 1976

- 1975

- 1974

- 1973

- 1972

- 1971

- 1970

- 1969

- 1968

- 1967

- 1966

- 1965

- 1964

- 1963

- 1962

- 1961

- 1960

- 1959

- 1958

- 1957

- 1956

- 1955

- 1954

- 1953

- 1952

- 1951

- 1950

- 1949

- 1948

- 1947

- 1946

- 1945

- 1944

- 1943

- 1942

- 1941

- 1940

-

Results For

-

-

-

State

- Alabama

- Alaska

- American Samoa

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- District Of Columbia

- Federated States Of Micronesia

- Florida

- Georgia

- Guam

- Hawaii

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Maine

- Marshall Islands

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Northern Mariana Islands

- Ohio

- Oklahoma

- Oregon

- Palau

- Pennsylvania

- Puerto Rico

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virgin Islands

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

BEARINGS

CUTTING-EDGE ENGINEERING, ENHANCED DURABILITY

ENGINEERED FOR TECHNICIANS

Ultimate engineering for ultra strong parts.

Designed for strength, endurance and performance.

Greaseable Sintered Bearings™

Engineered to excel under high heat and heavy loads.

The very heart of our technology, our industry-leading self-lubricating sintered bearings are engineered with our proprietary formula to last 4x longer than polymer. Built for maximum toughness, they are designed to operate in a high heat environment without deforming, and withstand high impact and loading to keep going strong. Plus, their porous nature means they are continuously self-lubricating.

Sintered Bearing Technology

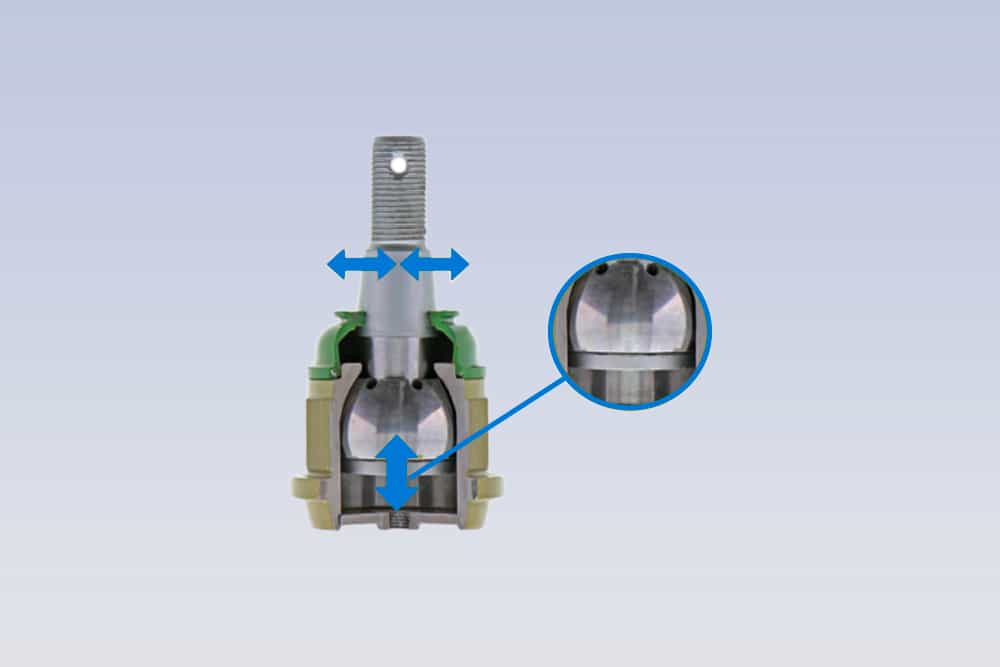

Patented Snap-In Bearing™

Engineered solution to eliminate memory steer.

Combining extreme durability with innovative engineering, the snap-in bearing is designed to address the challenges of memory steer on solid axle applications. Patented design allows for pivoting motion which permits the pin to realign and prevent binding.

Oversized self-lubricating sintered bearing with large contact area and stud work together to withstand greater loads in all ranges of movement to provide extended part life.

Exclusively Featured on TTX Parts

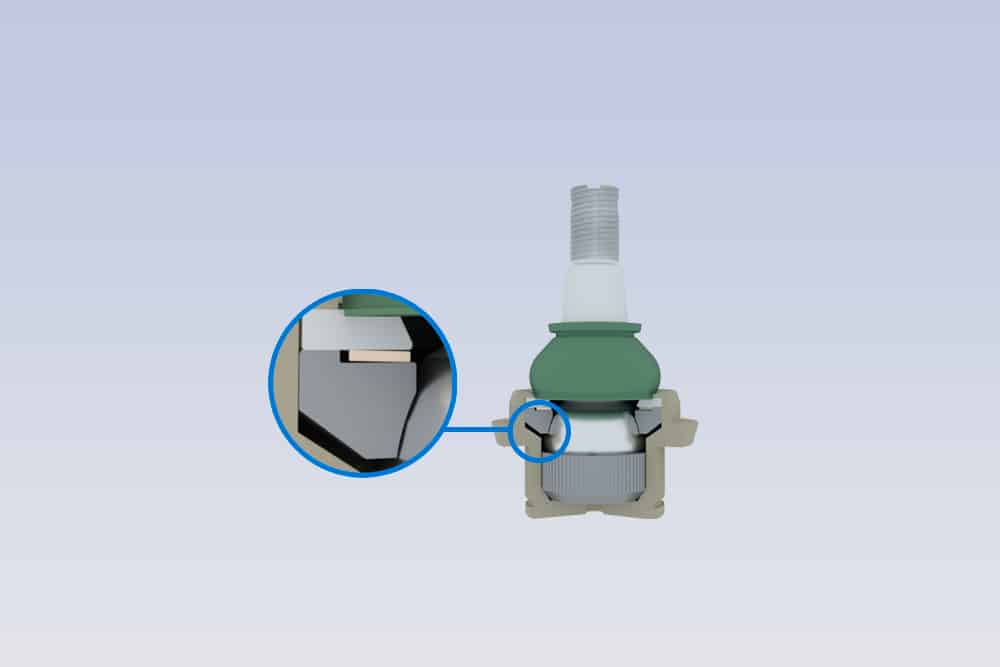

Patented Dynamic Control Bearing™

Optimizes service life and performance by self-calibrating preload.

Engineered to provide exact, self-calibrated preload, the dynamic control bearing is designed to limit flattening of the Belleville disc spring. This creates a tighter and stiffer assembly over the entire part life and provides extra strength under all service conditions.

Exclusively Featured on TTX Parts

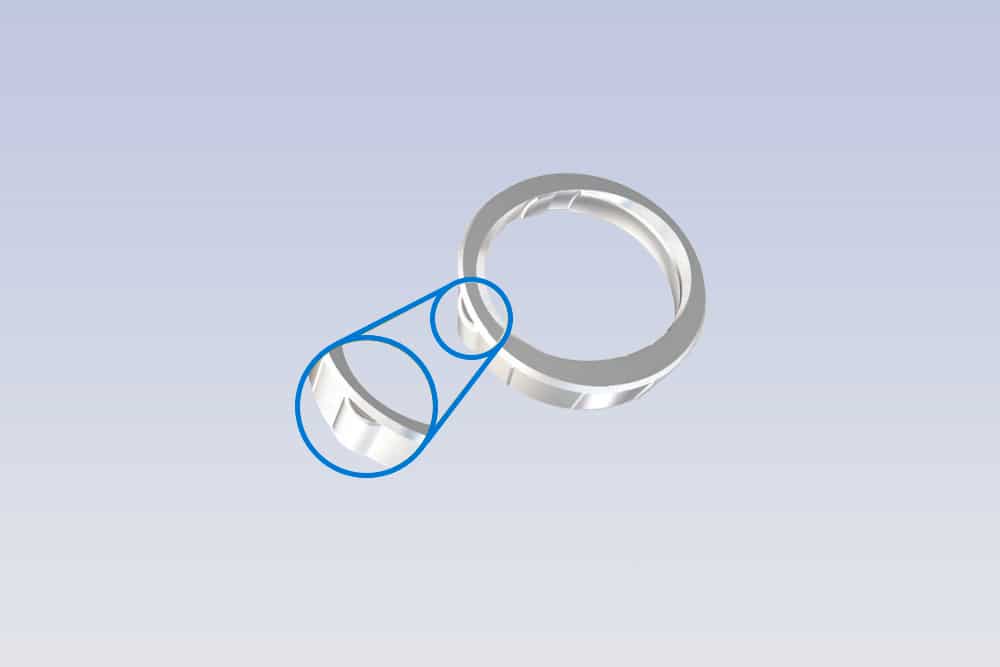

Patented Directional Bearing™

Engineered to optimize load distribution.

The patented directional bearing is engineered to overcome the limitations of elliptical stud openings. The design allows for a self-lubricating sintered bearing to be located inside directional housings, providing additional contact area and greater pressure distribution for less wear.