EVERYTHING YOU EVER WANTED TO KNOW ABOUT FASTENERS (BUT WERE AFRAID TO ASK)

A fastener is a piece of hardware that mechanically joins or fastens together two or more objects. From nuts to bolts to washers and more, fasteners enable a non-permanent connection to be made, and they can typically be removed or disassembled without causing damage to the adjoining parts.

In our on-demand webinar, our experts show you all the ins and outs of fasteners for successful and secure installs and repairs. Here are some helpful tips and key information to get started.

Use the Right Fasteners for the Job

When it comes to threaded bolt fasteners, the threads are split up into two basic types, imperial and metric. They are neither compatible nor interchangeable.

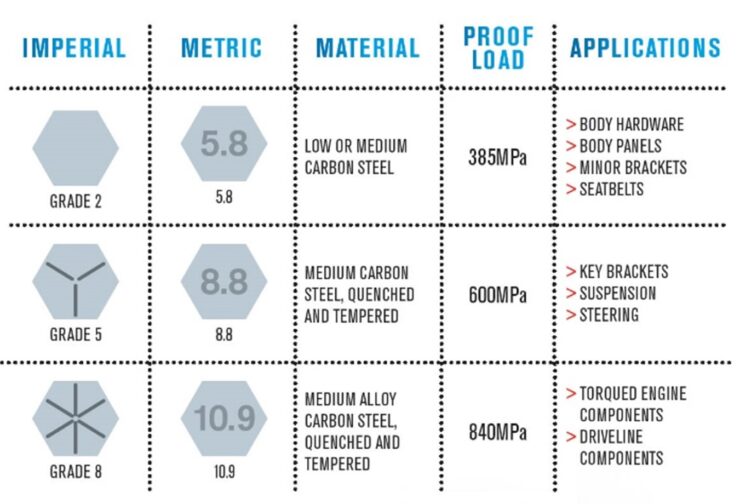

Hex bolts with a six-point head are the most common (see below). They come in imperial and metric sizes, measured from flat to opposite flat. They are graded according to strength, and the higher the grade number, the stronger the bolt. They can be made of materials such as low carbon steel for minor brackets, all the way up to durable medium alloy carbon steel that has been quenched and tempered for driveline and torqued engine components. Imperial hex bolts can be differentiated by the graduation or number of slots, if any, on their heads. If they are metric, their heads will feature numerical values.

From six-point hex to Allen head to triple square, there is a multitude of internal (female) and external (male) fastener head types. Make sure you use the correct type and size fastener for the job.

It is important to note that you should always replace a fastener with one of equal or higher grade. Never down-grade, because you may end up with a fastener that is not strong enough for the application.

The Nuts and Bolts of Fasteners

Nuts are mechanical fasteners that have a threaded hole. They are attached to a bolt, screw or stud to provide a clamping force and prevent axial movement. Washers are used to distribute the load from the nut or bolt and/or to keep the assembly from loosening. Washers come in many different sizes and materials to accommodate a variety of purposes.

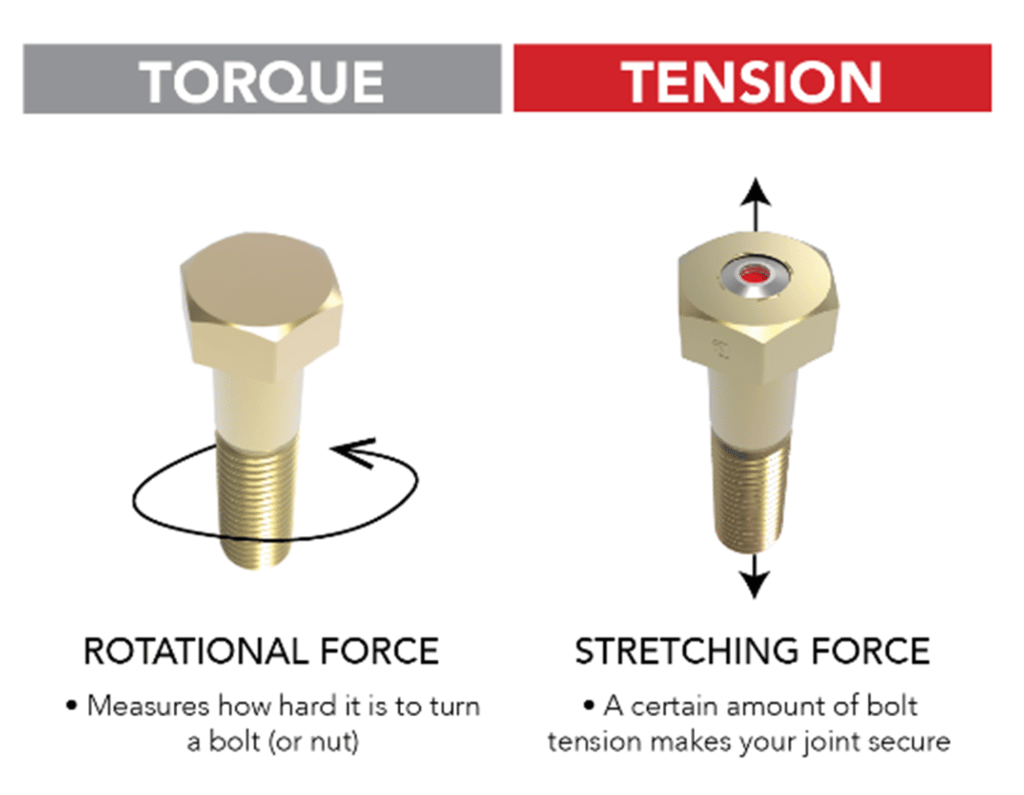

For fasteners to work correctly, you need to create tension in the assembly (see below). Torque is used to turn a nut or bolt, which stretches it, making it a solid spring clamping the two materials together. If the proper torque is not applied, the system will not work as intended.

5 Pro Tips for Fasteners

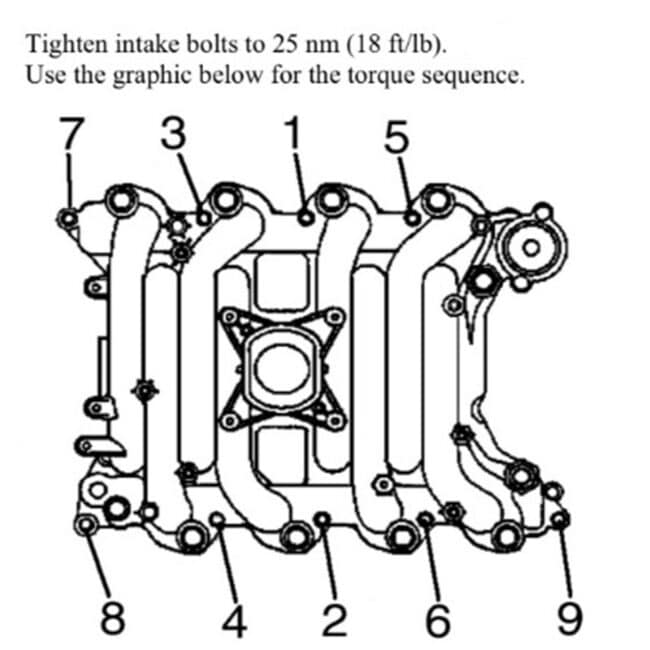

- Apply the Correct Torque: Always consult the vehicle’s service manual and apply the correct torque specifications and fastening sequences, where applicable, per the example below.

- Use the Right Tool: Always torque a fastener to its correct specification using the appropriate tool. This is the only way to ensure the system will work properly.

- Be Careful Using Anti-Seize on Threads: Anti-seize can drastically alter the torque of a fastener depending on its grade and material. Only use anti-seize when it is called out in the procedure or be sure to calculate the torque reduction for your application.

- Follow Re-Use Instructions: Always check the service manual procedures for discard hardware notifications. Do not re-use the fastener if instructed to discard it. If re-use is acceptable, ensure fastener is free from corrosion and clean before reassembly.

- Take Care with Castellated and Slotted Nuts: Always advance the nut to line up the slot or castellation. Backing off will cause a loss of tension and an unsafe connection.

Summary

No matter the job, always refer to the factory service manual for correct component removal and installation methods, as well as fastening torque values and instructions, where applicable.

To learn more about fasteners, along with essential tips and tricks, watch the webinar: Everything You Ever Wanted to Know About Fasteners (But Were Afraid to Ask).