THE GOOD, THE BAD AND THE UGLY: WHAT TO LOOK FOR IN A QUALITY HUB

Wheel hub bearings have an impact on several vehicle performance factors, such as tire wear, braking control, stability in both straight lines and turns, as well as overall safety and handling. They support the wheel load, allow for the friction-free movement and rotation of the wheel and can even play a role in providing a wheel speed sensor signal to vehicle drive systems.

When the rubber hits the road, wheel hub assemblies have a lot on their plates. Want to get a better idea of what to look for in a quality hub? Our webinar will show you all you need to know.

Types of Wheel Hub Bearings

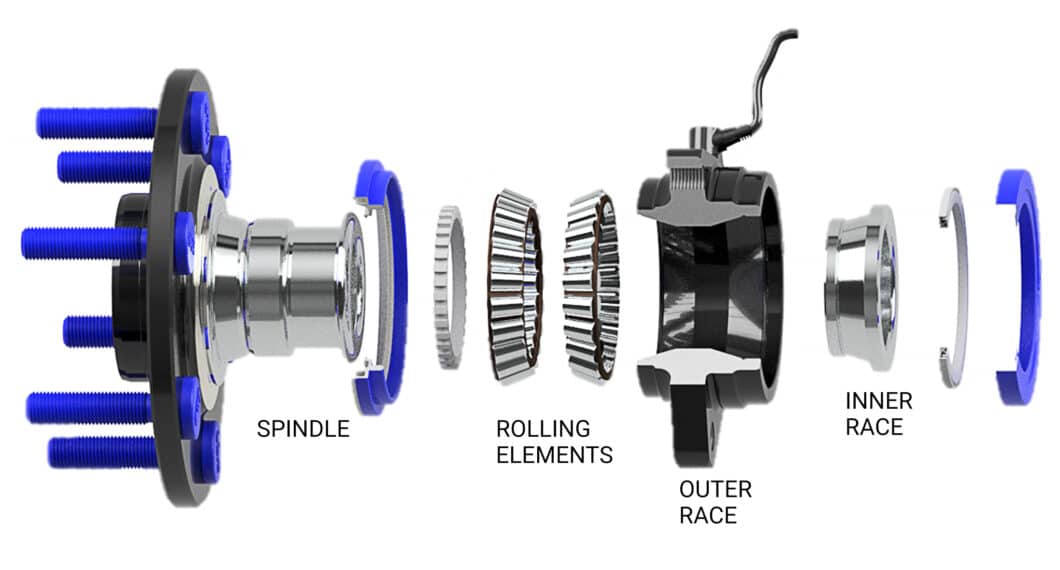

Modern Hub Assembly Components

SPINDLE: The main body of a wheel hub, all components interact with the spindle. It includes a raceway to support the outboard set of rolling elements.

OUTER RACE: Sitting between the spindle and inner race, the outer race is bolted to the knuckle. Both sets of rolling elements hold it in place.

INNER RACE: The spindle is roll-formed onto the inner race to lock it into the assembly. It includes a raceway to support the upper (inboard) set of rolling elements.

ROLLING ELEMENTS: Held in place by a cage, rolling elements enable rotation between the outer race and spindle (and by extension, between the wheel and knuckle). Ball bearings, seen in smaller vehicles, roll with lower friction but have a lower carrying capacity. Tapered roller bearings, used in larger vehicles, increase friction but can withstand higher loads without failure.

Why Hub Bearings Fail

Hub assemblies typically fail because of vibration, which can be caused by many factors, including contamination, wear, impact and overheating.

What Makes a Quality Hub

Various upgrades have been introduced to quality hubs, in order to overcome challenges, perform better and last longer. For example:

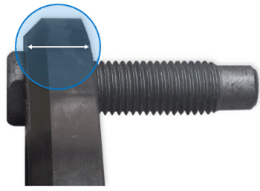

HUB SPINDLE: Increasing the thickness of the hub spindle adds strength, protecting it from warping under impact and safeguarding it against vibration due to runout.

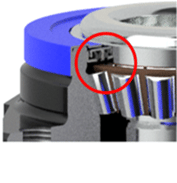

INBOARD SEAL: Found on the side that faces toward the vehicle, the inboard seal secures both the outer race and spindle of the assembly. Quality inboard seals will feature multiple sealing lips that redirect contaminants out.

Premium Hubs may also include a metal shield over top of this seal.

![]()

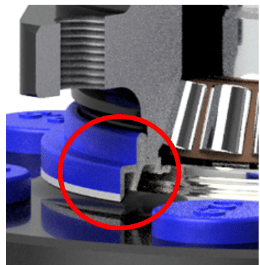

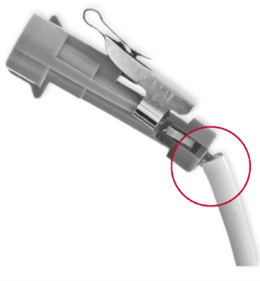

OUTBOARD SEAL: Positioned on the side that faces outward, the outboard seal is mounted on the outer race and seals against the spindle of the assembly.

Premium hubs will have robust seals and better shielding.

![]()

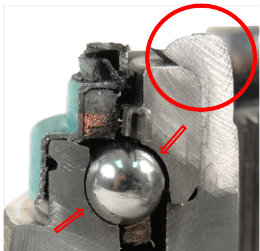

BEARING LOADING: To operate properly, the rolling elements in a hub bearing must be loaded to a certain specification. Too much loading can cause damage, while too little loading can leave components loose and cause premature hub failure. Most GEN 3 Hub assemblies require a specific torque applied to the axle or thru-pin nut to achieve the correct bearing loading.

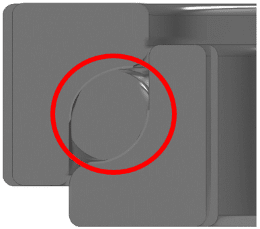

ROLL FORMING OF THE SPINDLE: Premium hub assemblies will incorporate a roll form design that pre-applies the bearing loading. This makes the hub less reliant on the torque applied to the axle nut, ensuring the longest service life possible.

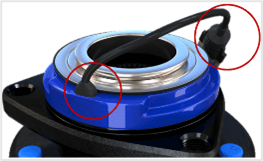

WHEEL SPEED SENSORS: The wheel speed sensor wire is often the reason for hub failure, which can be especially frustrating as the hub may be mechanically sound but not sending out a proper signal.

Premium hub brands increase the thickness of the wire sheath and add strain reliefs to protect the wires, ensuring accurate and continuous wheel speed sensor function.

LUBRICATION: The type of grease used in a hub is critical to its performance and service life. Premium hubs will use advanced Nanoceramic grease that reduces friction, resists corrosion, retains viscosity at high and low temperatures and withstands water ingress.

CORROSION PROTECTION: Keeping a hub assembly corrosion free is the best way to protect the seals and keep contaminants out. Premium hubs will feature a coating that prevents corrosion from migrating into the internals.

ADDED HARDWARE: The best hub assemblies will include a full complement of replacement hardware, for a faster and easier install.

Summary and Final Tips

When replacing wheel hub bearings, always refer to the vehicle’s service manual for the proper procedures and torque specs. Remember to treat any wheel speed sensor components with care to ensure accurate function, and never apply excessive force or heat to remove parts.

Ultimately, choose a hub bearing assembly that is built strong enough to do the job right and provide a long service life. For the best outcomes, look for:

- Better seals to keep out water and debris

- Roll-forming that locks internal components for a set preload

- High-quality ABS cables that guard against perforation and contaminants

- Premium replacement hardware that speeds up installation

For more sound advice from the pros, watch the webinar, The Good, the Bad and the Ugly: What to Look for in a Quality Hub.