Work Hard, Play Hard: Toughen Up Your Hybrid Jeep® Chassis with Supreme Parts

Today’s Jeep drivers can have it all, heavy-duty performance combined with the efficiency of a hybrid, all while being able to make cool custom modifications. But, as with any hybrid vehicle, there are some factors to consider.

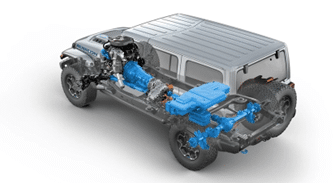

Let’s take a look at Jeep’s first hybrid, the Wrangler Rubicon 4XE. This vehicle carries roughly 1,000 lbs of extra weight from the motor, battery and other components, putting strain on the axle system. These heavy vehicles need chassis parts that can handle extreme forces from the instant torque that the 4XE’s two electric motors provide and the modifications Jeep owners love to make.

Let’s take a look at Jeep’s first hybrid, the Wrangler Rubicon 4XE. This vehicle carries roughly 1,000 lbs of extra weight from the motor, battery and other components, putting strain on the axle system. These heavy vehicles need chassis parts that can handle extreme forces from the instant torque that the 4XE’s two electric motors provide and the modifications Jeep owners love to make.

With the hybrid system plumbed through the powertrain, the 4XE still has the original Jeep advantage of front and back solid axles for excellent off-road performance. But that extra half ton of weight on the hybrid versus the standard Wrangler means the chassis parts must be ready for extra punishment – yet they are often the same parts. No matter the make or model, the Corporate Average Fuel Economy (CAFE) Standard and vehicle lightweighting continue to influence OE undercar component designs.

Fortunately, Mevotech Supreme builds tougher, beefier, more durable aftermarket components, providing a longer part life and a better long-term ride. And the premium Supreme line has phenomenal coverage for Jeeps. From wheel bearings to tie rod ends to stabilizer links and control arms, Supreme has basically everything you need from the wheel in.

Mevotech Territory Manager, Barry Sullivan, and Technical Sales Manager, Austin Loomis, discuss all of this in their fun Drive Along Video They recently took to the road in a 2022 Jeep Wrangler Rubicon 4XE and chatted about how Supreme parts are engineered to stand up to the challenges heavy hybrids and modifications can bring.

The Ways Supreme Outpaces OE

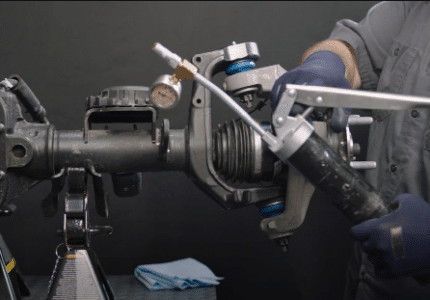

Mevotech engineers superior driveline, steering, suspension and hub assembly components for the kind of action these Jeeps face on- and off-road. No matter the vehicle, it’s important to equip it with parts that are built for durability and a long service life. Identifying OE wear patterns and faults, our engineers are dedicated to improving upon the OE designs. OE ball joints for the 4XE, for example, will have plastic bearings inside, while Supreme uses much tougher sintered metal bearings.

Better Ball Joints

When you look at Jeeps, which often have a bigger tire and wheel package added on, a lot more strain is put on components. Whenever you’re pushing more rubber than the vehicle is designed for, it’s going to wear out those OE components much faster – and ball joints are no exception. The original ball joints feature non-greaseable plastic bearings and the standard housing design. This reduces part manufacturing cost and overall part weight. However, an engineered solution is required for vehicles such as Jeeps, which typically encounter high-load and high-heat service conditions.

When you purchase a Mevotech Supreme ball joint for the Jeep Wrangler JL/JLU or Gladiator JT platforms, you’re getting the benefits of a sintered metal bearing, greaseable design, patented locking boot technology, anti-corrosion coating, and then it’s going to have knurling on the outside of the pressing surface for a snugger fit. Check out the Supreme Ball Joints Drive Along Video to learn more.

When you purchase a Mevotech Supreme ball joint for the Jeep Wrangler JL/JLU or Gladiator JT platforms, you’re getting the benefits of a sintered metal bearing, greaseable design, patented locking boot technology, anti-corrosion coating, and then it’s going to have knurling on the outside of the pressing surface for a snugger fit. Check out the Supreme Ball Joints Drive Along Video to learn more.

Better Boots and Housings

To protect ball joint internals from all the dirt, salt, mud and grunge Jeeps encounter, Mevotech Supreme MS25574 and MS25575 front upper and lower ball joints have an innovative dust boot solution. The patented Locking Dust Boot seals out harmful road contaminants while the upgraded housing forging profile increases part strength for a longer service life.

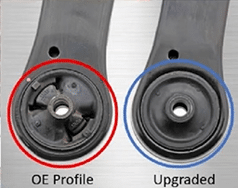

Better Bushings

Supreme bushings, such as those on our control arms (far right), are generally more reinforced than the OE profile and a more robust product overall. Featuring high-grade rubber with filled-in voids for toughness and knurling for added bite, these bushings aren’t prone to cracking or tearing like the OE versions.

Better Hubs

Some manufacturers may try to save on material and leave a little bit of exposed wiring from the sensor to the hub. This is a fault point that our engineers have identified on other products, and so we make sure our coating goes right up into the hub. The molded, thicker abrasion-resistant cord guards against perforation and contaminants at both the sensor and plug ends.

Other advantages of Supreme hubs include:

- Roll-form construction that locks internal components for a set preload

- Thicker flange that provides additional stability and protection

- Quantum Sealing System with a multi-lip profile that provides layers of defence

- NanoCeramic lubricant that withstands extreme temperatures, resists corrosion, and retains viscosity

- All the hardware needed for a quick and easy install

- Repel-TEK™ anti-corrosion coating applied to every surface

Especially in winter, in areas where there’s a lot of salt used on the roads, wheel bearings need quality anti-corrosion coating. Otherwise, as Barry says in our Supreme Hubs Drive Along Video “Your wheel bearing within one to two winter seasons becomes, literally, a boat anchor. It is brutal.” Mevotech Supreme hubs even come with new spindle mounting bolts and a new axle nut for a complete install out of the box.

Jeep Adventures Need Supreme Products

The Wrangler Rubicon 4XE combines the communities of hybrid/electric owners and Jeep owners – those looking for the full Jeep experience while increasing efficiency. And being Jeep enthusiasts, they also like to make modifications – those big tires, maybe a steel bumper in the front, plus a winch and even a trailer.

Before they know it, they’ve added even more weight to an already heavy hybrid. It’s said that roughly 80% of Jeep owners modify their vehicles in one way or another. These mods will definitely put strain on the suspension, so tougher products – like sintered metal inside, better dust boots, tougher bushings, superior anti-corrosion coating – are required. Supreme delivers all this and makes installation faster and easier with all you need in the box for a complete install.

Ready for Your Own Jeep adventure?

Here are a few tips: closely inspect the tires, 4×4 system, fluids, steering, suspension, lights, brakes, etc. Pack food, water and essential gear. Buckle up and get out there!

Here are a few tips: closely inspect the tires, 4×4 system, fluids, steering, suspension, lights, brakes, etc. Pack food, water and essential gear. Buckle up and get out there!

From rock climbing to getting stuck on purpose, watch the Build Your Own Adventure Drive Along Video to find out what Austin and Barry would do if they could take the Rubicon 4XE anywhere in the world for two days.

Better still, watch the entire series of 4 Supreme Drive Along Videos.