Top 5 Indicators of Bushing Failure and What to do About Them

When your vehicle is new it provides the performance and handling that the original manufacturer intended, ensuring your ride is smooth and enjoyable. As your vehicle ages, its suspension will start to sag and the ride will begin to feel softer. There may be more play in the steering wheel and you may start to hear noises when accelerating or braking. The entire geometry of your vehicle will change with age and mileage, placing additional stress on most steering, suspension and driveline components, contributing to accelerated part failure.

When analyzing changes in a vehicle’s ride and looking for failures, control arm bushings are often overlooked. These bushings take most of the force during braking, accelerating and cornering. Their performance is especially relevant for suspension health in aftermarket vehicles. As the bushings in control arms wear, additional loading is placed on the vehicle’s suspension system, creating unwanted tire camber. For tire life and ride quality it’s critical that your vehicle’s bushings be in good working order, but first you need to recognize the signs of failure. Here are 5 indicators of bushing failure to watch out for:

- A feeling of pulling when braking or accelerating

- Uneven tire wear from left to right

- Tire wear patterns that show signs of camber wear

- A clunking noise during accelerating or braking

- A loose feeling in the steering when turning corners

HelpLavoro.it – Oferta de empleo ViviWellness – Buscar 5 Entrenadores y aspirantes a Entrenadores en el sector de la Belleza y el Fitness escape room tarragona miedo abcardio health – abcardio salud y fitness

How OEM Bushings are Designed

Control arm bushings are made of soft materials such as rubber and various types of polymers. Their job is to provide a cushion between two metal parts, reduce road harshness, dampen noise and control vibration. OEMs often add reliefs, or voids, to bushings to provide lower stiffness in one direction, essentially to tune the performance of the suspension system. However, these voids can create a point of weakness in the bushing material. This can result in the material tearing or cracking and may cause increased stress on the suspension system.

What to look for in Aftermarket Bushing Design

Since voids in control arm bushings can create a weak point, the best aftermarket manufacturers have come up with alternative designs, strategically reducing or completely removing the voids to strengthen the bushings. If done right, this engineering can maintain vehicle handling longer, extend tire life and reduce vehicle noise and vibration when driving.

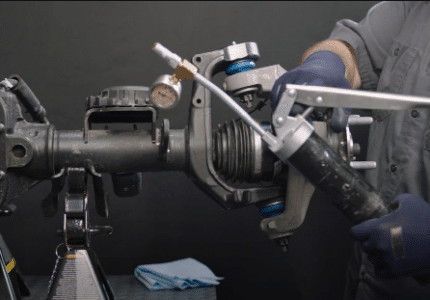

The best aftermarket bushing manufacturers understand that different types of vehicles have different needs, and they create unique designs to accommodate them. In the case of light to medium duty vehicles, look for bushings that are engineered with minimized voids for a critical balance of stiffness and flexibility. This will optimize ride quality while accounting for the lighter vehicle weight. The best aftermarket bushings will come with alignment indicators to make it faster and easier for technicians to orient the voids during installation.

For larger and working vehicle applications, look for aftermarket bushings that are engineered without voids to minimize the potential for tearing while supporting the heavier weight loading. Solid bushings will provide optimal stiffness in working vehicles where resilience is paramount. By including smaller voids or no voids at all in bushings based on the load factor, the best aftermarket control arm bushings will have a longer service life and deliver a smoother, firmer ride.

Summary

Often overlooked, bushing failure can cause a ripple effect of pressure and wear on surrounding components. This wear ultimately results in additional loading and pressure on the steering, suspension and driveline components. Over time, this constant stress contributes to accelerated part failure.

Here at Mevotech, our Supreme and TTX control arm bushings are made of highly durable material that is resistant to extreme temperatures and has improved memory properties. Our aftermarket bushings are built with application-specific upgrades to make them work harder and last longer. They are engineered with voids or without, according to your aging vehicle’s needs and the type of work it will be doing. Our bushings make allowances for changes in your vehicle’s geometry and bring your suspension back up to spec to ensure proper wheel alignment, increase tire life and lower your long-term maintenance costs. Designed with technicians in mind, Mevotech solutions are engineered to renew your ride and keep your vehicle on the road.