DON’T GIVE ME ANY FRICTION! THE MAGIC OF SINTERED BEARINGS

What Are Ball Joint Bearings?

On a ball joint, the bearing is the contact surface used between the ball pin sphere and the ball joint housing. The bearing’s material has a huge impact on how it will perform and wear.

In our on-demand webinar experts discuss the characteristics, pros and cons of the different ball joint bearing options and what you need to consider when making your choice.

Important Qualities to Look For in Ball Joint Bearings

- High stability and durability throughout their service lifetime

- Minimal deformation under stress and heat

- Good chemical resistance to lubrication grease and other substances

- Low coefficient of friction and wear factor

- Superior endurance and strength

- Ability to hold up under high loading and high impact situations

Metal On Metal vs Polymer vs Sintered Metal

Metal On Metal

- Outdated technology

- Housing is used as bearing surface

- Constant lubrication required

- High friction

- Increased breakaway torque

- Fretting corrosion risk

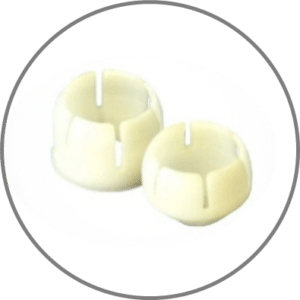

Polymer Bearing

- Very low friction

- Heat sensitive

- Reactive to contamination

- Lasts the length of the warranty

- Low cost

- Typically found in non-serviceable, sealed components

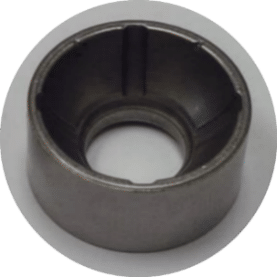

Sintered Metal Bearing

- Low friction

- Impervious to heat

- Durable

- Withstands high-impact loading

- Self-lubricating

- Typically found in serviceable components

Why Sintered Bearings Are Superior

Polymer and sintered bearings both have their place in the aftermarket, and their suitability depends on the demand put on the vehicle. OEMs originally introduced polymer bearings as a lighter, lower-cost alternative to metal. But when it comes to friction surfaces on a suspension joint, sintered bearings are the optimal choice. They can operate in a high heat environment without deforming and they simply last longer. In fact, lifecycle testing has shown that sintered bearings can last 3 times longer than plastic and 10 times longer than milled metal.

To keep them running smoothly, any grease which carries a GC-LB certification can be used to service the ball joint. Additionally, spaces within the sintered grain structure can retain grease, which means the bearings are continuously self-lubricating.

Mevotech’s Sintered Technology

Our sintered bearings are made of a proprietary powdered metal mixture that includes iron, zinc, copper and nickel. The metal powder is compacted under intense pressure and then sintered at elevated temperatures to achieve the required strength, hardness and density. After sintering, the bearings are impregnated with oil to ensure permanent lubrication. While more expensive to produce than polymer, sintered bearings have a longer service life.

Overall, sintered bearings are the more durable, better-performing choice. Professional Technicians generally choose sintered bearings for applications where load and wear patterns would benefit from the additional strength of a lasting metal design.

Want to know more? Watch the brief webinar to get a look inside the parts and see the manufacturing processes.