WHY GOOD BEARINGS GO BAD, WHY SMART HUBS FAIL AND OTHER MYSTERIES SOLVED!

When installing wheel hub bearings, common oversights can cause them to fail prematurely. Simple errors during servicing and maintenance can also determine how well a new hub assembly will perform and how long it will last. Our webinar will show you best practices and how to avoid common errors during the installation, servicing and maintenance of replacement wheel hub bearings.

What Do Bearings Do?

Bearings enable the wheel to rotate and move friction-free. One side of the bearing is fixed to the suspension and the other side rotates with the wheel. Many bearings today also have a wheel speed sensor that controls ABS and other systems that help keep vehicles safe on the road.

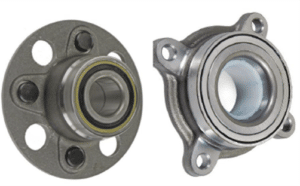

The 3 Generations of Bearings At-a-Glance

Automotive bearings use two types of rolling elements, ball bearings and roller bearings. Over the years, three generations of bearings have been developed:

GENERATION 1: Used on driven and non-driven wheels

- Are still found on some import vehicles

- Feature double-row ball bearings or tapered roller bearings that cannot be disassembled

- Need a spindle or axle thru-pin to keep assembly together and set preload

- Are pre-lubricated and sealed

- May have an ABS encoder ring as one of the seals

GENERATION 2: Typically used on non-driven wheels

- Are generally a hybrid between Gen 1 and Gen 3, with one of the mounting surfaces already pre-applied to the bearing

- Use double-row ball bearings that cannot be disassembled

- Feature a hub or mounting flange with a rotating inner or outer ring

- Are pre-lubricated and sealed

- May feature an ABS encoder ring

GENERATION 3: Used on driven and non-driven wheels

- Are found on most of today’s vehicles

- Come as a complete assembly with both wheel and knuckle mounting flanges

- Feature double-row ball bearings or tapered roller bearings that cannot be disassembled

- Premium products will include roll-forming to set initial bearing preload

- Are pre-lubricated and maintenance free

- May feature an ABS encoder ring

Part Replacement Best Practices

It is important to understand the type of bearing you are working with and to follow the proper installation procedures using the appropriate tools. Remember to always tighten nuts with a torque wrench to the correct specifications so the bearings are set to the proper preload.

GENERATION 1

- Use caution when pressing components into place

- Make sure the ABS encoder is undamaged and oriented correctly before pressing into the knuckle

- Verify that the bearing and any accompanying snap rings are fully seated

GENERATION 2

- See Generation 1 – installation procedures are similar but with one mounting flange pre-fitted

- May need special tools to remove or install

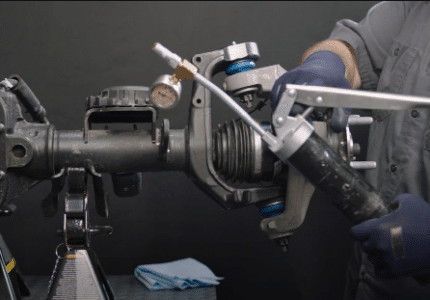

GENERATION 3

- Clean the knuckle and bore to ensure the assembly is properly seated

- Never omit the brake dust shield that fits between the hub and knuckle

- Pay particular attention to the seals on 4X4 front hub assemblies that use a vacuum hub locking system

Diagnostics

Generation 3 is the most common type of hub found on vehicles today, and as with all replacement parts, it is important to diagnose the reason for the previous part’s failure. You want to treat the cause not the symptom. Some causes of Gen 3 hub failure include hub runout condition (over .004” is bad), contamination, poor alignment/unbalanced tires, dragging brake and other underlying issues.

What Not to Do During Servicing

DON’T

- Damage wheel speed sensors, connectors or wires

- Heat up the knuckle or hub with a torch

- Use pneumatic or electric impact wrenches

Maintenance Dos and Don’ts

DO

- Validate replacement parts

- Clean mating surfaces to ensure proper fitment

- Utilize the proper tools for the job

- Torque all fasteners to spec

- Apply anti-seize only to appropriate surfaces

DON’T

- Damage surrounding areas when removing the old part

- Handle the assembly by the speed sensor cable

- Use excessive force to remove the old hub

- Pry or chisel a hub away from the knuckle (Use a rotational force to break galvanic corrosion instead)

Preventing Damage During Unrelated Repairs

Take care when performing certain repair jobs that can potentially cause damage to wheel hubs, including:

- Performing brake jobs: removing stuck rotors, over-lubing slide pins

- Removing CV axles

- Replacing broken wheel studs

- Replacing or repairing wheel speed sensors

Summary and Top Takeaways

When replacing wheel hub bearings, always attempt to find the reason for the failure to avoid the same thing occurring to the new part. Always treat any wheel speed sensor components with care to ensure accurate function. Never use heat or excessive force to remove parts and always torque fasteners to proper specification. Watch the webinar, Why Good Bearings Go Bad, Why Smart Hubs Fail, for more tips and tricks from the pros.