Save Bay Time & Money: 9 TTX™ Labor Savers™ that Maximize Your Bay Efficiencies

When you look at saving costs in your shop, shaving time off installations can really help. If you consider that the average cost to run just one automotive bay is $90.00 per hour or $1.50 per minute, any advantage that will speed up installs is worth a second look. Your customers will also appreciate a job done faster – especially when it comes to high-usage fleets and trucks. They need long-lasting parts engineered for extreme service and designed for quicker installs to get them back on the job faster. That’s why TTX – Terrain Tough Extreme parts are built to last, work hard and maximize bay efficiencies.

Show Me the Money

Our TTX Labor Savers are engineered with technicians in mind. They include design improvements to simplify installation, along with all the essential tools and hardware in the box at no extra cost. Here are 9 Labor Saver examples that can save you time and money during installation:

- Press Through Boot: This design enables the ball joint to be installed without removing the boot, saving time and reducing the possibility of damaging the components during installation. Average savings: 2-3 minutes or $3.00-$4.50

- Integri-Boot: The boot is vulcanized to a steel plate and roll formed into the assembly. Since the boot is preinstalled onto the ball joint, installation time is saved and the ball joint remains protected. Average savings: 2-3 minutes or $3.00-$4.50

- Bootstaller Tool: In applications where a boot must be installed, we include a custom-fit tool to seat the boot perfectly and protect it at the same time. Plus you get to keep the tool to use again when needed. Average savings: 3-5 minutes of looking for a proper installation tool or $4.50-$7.00 + a new tool

- Easy Snap Locking Pin: Rather than having to push the cotter pin through the islet on the castle nut and bend it, you just push in the easy snap pin and your ball joint is securely locked. It’s all done with one hand, no tools, no problem. Plus, the pin has a corrosion-resistant coating so it can be quickly and easily removed. Average savings: 1-2 minutes finding and using needle nose pliers or $1.50-$3.00

- Quick Loader Plate: Ball joint attachment fasteners pressed into the attachment plate enable the ball joint to be installed with a single tool. Average savings: 4-6 minutes fumbling around with 2 wrenches or $6.00-$9.00

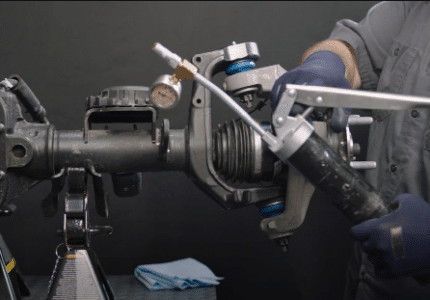

- Installation Adapters: Provided with all TTX ball joints that have an installation flange less than ¼” wide, our installation adapters prevent ball joints from being damaged during installation. They are made from high-strength alloy steel and designed to fit snugly over the top of the pressing surface to give you a larger flange area. No more making your own cup adapters when standard ball joint cup kits let you down – especially in Asian and European vehicle applications. Our installation adapters ensure the perfect install every time, plus you get a new tool for your kit. Average savings: 5-10 minutes finding/making an appropriate adapter or $7.50-$15.00 + a new tool

- Pre-Applied Thread Locker: Nylok Precote® 85 thread locker is pre-applied on hardware, saving time, adding an additional layer of security, plus providing great vibration and temperature resistance. Average savings: 3-5 minutes finding and applying thread locker or $4.50-$7.50

- Additional Hardware: TTX parts come with all the hardware required to complete the install. Our hardware has been upgraded from the usual OE grade 8 to grade 12.9 strength, and corrosion-resistant coating has been pre-applied to ensure it lasts. Average savings: 1-2 minutes finding the hardware you need or $1.50-$3.00

- Specialized Installation Tools: We include specialized, application-specific installation tools when they are not readily available. For example, the 2008-2019 RAM 4500/5500 upper front ball joint threads in and needs a 60mm socket to remove it. Since you may not have that socket on hand, our TXMS25519 ball joint comes with a 60mm socket made of hardened steel that you can use to remove the OEM ball joint and install the TTX ball joint in the steering knuckle. Plus it adds a new tool to your arsenal for free. Average savings: the cost of a 60mm socket and the time spent finding/acquiring one: $50.00-$80.00 in savings + a new tool

High-performance TTX parts with Labor Savers can make every installation faster and easier, and at the same time ensure surrounding components are protected. Mevotech puts the tools and hardware you need at your fingertips – included in the box at no extra cost – to boost your bay productivity and your bottom line.