THE LOW-DOWN ON CONVENTIONAL STEERING SYSTEMS

We all know how important steering function is to driver and passenger safety. There are two basic types of power steering systems: rack and pinion and conventional. In our on-demand webinar, our experts compare both systems and cover everything you need to know about conventional steering.

CONVENTIONAL VS. RACK & PINION

While rack and pinion is pretty much the standard now, you will still find conventional (steering gear) systems on today’s larger SUVs, heavy-duty trucks and vans, as well as most domestic vehicles built before 1980.

SIMILARITIES:

Both rack and pinion and conventional steering systems use hydraulic pumps to aid the power assist.

DIFFERENCES:

Rack and Pinion Steering – This is a streamlined system, compared to a conventional steering system. It uses pressurized fluid or electric motors to move a rack back and forth to turn the wheels.

Conventional Steering – This system uses a steering box, with fluid controlled by a spool valve on a torsion bar that responds to driver input. The steering box contains gears that transmit driver input to the Pitman arm. The Pitman arm is connected to the linkage and provides the movement required to turn the wheels. Some systems may have an idler arm that works in tandem with the Pitman arm to support the linkage.

THE DIFFERENT TYPES OF LINKAGE SET-UPS & HOW TO ADJUST THEM

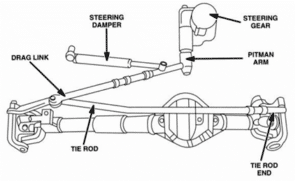

CROSS STEER

Description: On a cross-steer system, the steering knuckles are directly connected to each other by an adjustable tie rod. The Pitman arm is connected to the linkage by a draglink to either of the steering knuckles or to the connecting tie rod end. This connection is also adjustable.

Inspection & Adjustment: Start by checking all ball joint connections for play. Always follow the inspection and adjustment procedures outlined by the manufacturer. Some may ask you to adjust the total toe and then the drag link, while others may ask you to set the right-side wheel and then the left.

HALTENBERGER LINKAGE

Description: The Pitman arm is connected by linkage to the right-side steering knuckle. This linkage can be referred to as a center link, drag link or simply as a tie rod. The left-side steering knuckle is driven by a tie rod assembly connected to the center link, drag link or tie rod.

Inspection & Adjustment: Start by checking all ball joint connections for play. Always follow the inspection and adjustment procedures outlined by the manufacturer. Some older systems may only have a total toe adjustment. In this case, the steering wheel may have to be removed and repositioned.

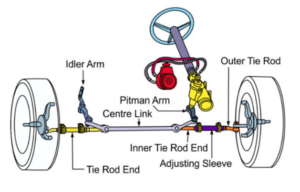

PARALLELOGRAM LINKAGE

Description: This system uses a center link driven by the Pitman arm and supported on the opposite end by an idler arm. Left and right tie rod assemblies relay movement to the steering knuckles.

Inspection & Adjustment: Start by checking all ball joint connections for play. Always follow the inspection and adjustment procedures outlined by the manufacturer. Toe can be adjusted independently. As with all steering systems, it is important to ensure the steering wheel is level and locked before any adjustments are made.

SUMMARY

The steering system is critical for getting you where you need to go, but not all systems are the same. Different systems have different configurations and components. They also have different adjustment points to set the vehicle’s alignment, which is essential for a smooth and straight ride. Want to know more? Watch our 30-minute webinar to get the low-down on conventional steering systems and the Pitman arms, idler arms, tie rod ends and other links that help them do their job.